In the world of industrial design and structural engineering, selecting the right material is rarely about picking the hardest metal available. It is a complex tradeoff between durability, weight, cost, and assembly time. Engineers and facility managers frequently find themselves debating between two primary contenders: the historical reliability of structural steel and the versatility of modular aluminum profiles. This choice often determines not just the immediate stability of a structure, but its long-term viability and total cost.

The question often posed is straightforward: Is extruded aluminum stronger than steel? However, the answer requires nuance. Strength is not a single metric; it comprises yield strength, tensile limits, stiffness-to-weight ratios, and geometric rigidity. Relying solely on raw metallurgical data can lead to over-engineered, heavy, and expensive solutions.

This guide moves beyond basic material properties to analyze the fabrication realities you will face on the shop floor. We examine the Total Cost of Ownership (TCO), assembly efficiency, and long-term application suitability to help industrial decision-makers choose the correct material for their specific operational environment.

Key Takeaways

Raw vs. Specific Strength: Steel generally holds higher raw yield strength, but extruded aluminum often offers a superior strength-to-weight ratio.

The Geometry Factor: How complex extrusion profiles achieve structural rigidity that would require costly fabrication to replicate in steel.

TCO Drivers: While raw steel is cheaper, aluminum extrusion reduces assembly time, labor costs, and finishing requirements.

Decision Verdict: Summary of when to stick with steel (high impact/heat) vs. when to switch to aluminum (precision/modularity).

Defining Strength: Yield, Tensile, and The Strength-to-Weight Ratio

To fairly compare these materials, we must first define what "strength" means in a practical context. If we look strictly at the raw force required to snap a solid bar in half, steel usually wins. However, industrial structures rarely fail because the material snapped; they fail because they bent excessively or became too heavy to support their own weight efficiently.

Raw Material Properties

When comparing common structural grades, such as ASTM A36 carbon steel against 6061-T6 aluminum alloy, distinct differences appear. Steel is denser, harder, and stiffer. Its Modulus of Elasticity—a measure of how much a material stretches under load—is roughly three times that of aluminum. This means that for a solid bar of identical dimensions, steel will deflect one-third as much as aluminum under the same load.

However, this stiffness comes with a significant weight penalty. Steel is approximately 2.5 to 3 times denser than aluminum. The following table highlights the differences in standard properties:

| Property | Structural Steel (ASTM A36) | Aluminum Alloy (6061-T6) |

|---|

| Density | ~7.85 g/cm³ (Heavy) | ~2.70 g/cm³ (Light) |

| Yield Strength | 250 MPa (36,000 psi) | 276 MPa (40,000 psi) |

| Modulus of Elasticity | 200 GPa (29,000 ksi) | 69 GPa (10,000 ksi) |

| Corrosion Resistance | Low (Requires coating) | High (Natural oxide layer) |

The Specific Strength Advantage

The comparison changes drastically when you factor in weight. This is known as "Specific Strength," or the strength-to-weight ratio. Aluminum excels here. Because it is so much lighter, you can use a larger volume of aluminum to achieve the same weight as a steel component. By increasing the volume—specifically the cross-sectional area—you can match or even exceed the rigidity of steel while keeping the total assembly weight lower.

For applications like mobile robotics, automotive frames, or aerospace components, specific strength is the critical metric. A steel frame might support the load, but its own weight could strain motors and reduce efficiency. An aluminum equivalent supports the payload while reducing the burden on the drive systems.

Deformation and Elasticity

Engineers also consider how materials behave when pushed to their limits. Steel typically exhibits a defined yield point followed by a period of plastic deformation. It will stretch and bend significantly before it snaps, providing a visual warning of failure. Aluminum behaves differently; 6061-T6 is somewhat more brittle in its failure mode compared to mild steel. It has an elasticity limit, but once exceeded, it may crack or fail with less plastic deformation than steel. This necessitates careful calculation of safety factors during the design phase to ensuring loads remain well within the elastic range.

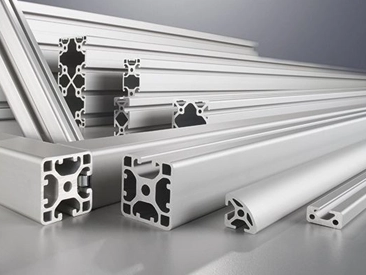

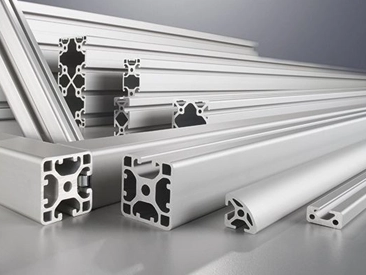

The Geometry of Aluminum Extrusion: How Design Impacts Rigidity

Material properties tell only half the story. The shape of the material—its geometry—plays an equally massive role in structural integrity. This is where Aluminum Extrusion shines. The extrusion process acts like a sophisticated "play-dough" press, pushing heated billet through a die to create complex cross-sectional profiles that are impossible or prohibitively expensive to roll in steel.

The Extrusion Advantage

Standard steel typically comes in simple shapes: solid bars, C-channels, or hollow square tubes. To increase the strength of a steel tube, you usually have to increase the wall thickness, which adds significant weight.

In contrast, aluminum profiles are engineered with internal webs, flanges, and supporting ribs. These features are designed to maximize the Moment of Inertia (resistance to bending) without adding unnecessary mass. An engineered aluminum profile might look larger physically than a steel tube, but it is mostly air and strategically placed metal. This geometry allows the profile to resist twisting (torsion) and bending forces far better than a simple hollow tube of the same weight.

Modular Rigidity

The T-slot design common in industrial aluminum framing adds stiffness exactly where it is needed. The added material required to form the slots and the central core of the profile contributes to the overall rigidity. Furthermore, this design allows for "modular rigidity." If a specific section of a machine frame experiences higher stress, you can bolster it by bolting on an additional support beam or gusset plate instantly. Modifying a welded steel frame to add support usually involves grinding, welding, and repainting—a downtime-heavy process.

Eliminating Weak Points

We must also address the "Heat Affected Zone" (HAZ). When you weld steel, the extreme heat alters the crystalline structure of the metal near the weld, often making it the weakest point of the assembly unless post-weld heat treatment is applied. Welds are also subject to human error and fatigue cracking.

Aluminum extrusion systems utilize mechanical fasteners. Brackets, bolts, and T-nuts hold the structure together. Because there is no heat involved in assembly, the material retains its full temper (e.g., T6) throughout the entire frame. The consistency of the material properties is uniform from end to end, eliminating the variable of weld quality.

Total Cost of Ownership (TCO): Material Cost vs. Assembly Efficiency

Procurement departments often look at the price per pound of raw material and immediately flag aluminum as the expensive option. While raw steel is indeed cheaper by weight, the raw material cost is often a small fraction of the total project cost. The Total Cost of Ownership (TCO) reveals a different financial reality.

Upfront Material Costs

Carbon steel is a commodity material with global abundance, keeping its raw price low. Aluminum requires more energy to refine and process, resulting in a higher base price. If your project involves a simple, permanent structure where aesthetics and weight are irrelevant—like a sub-floor foundation—the low cost of steel is hard to beat.

The "Hidden" Costs of Steel

The initial savings on steel quickly erode when you factor in fabrication. Steel requires significant labor:

Cutting and Prepping: Steel must be cut, deburred, and often drilled precisely before assembly.

Welding: Skilled welders are expensive and in short supply. Welding consumes consumables (gas, wire) and requires certified labor for structural compliance.

Surface Finishing: Raw steel rusts immediately. Every steel frame must be painted, powder-coated, or galvanized. This adds a logistical step, drying time, and chemical costs.

Rework: If a welded steel frame is slightly out of square, fixing it involves cutting and re-welding.

The Aluminum ROI

Aluminum extrusion systems are designed to minimize labor, which is typically the most expensive resource in manufacturing.

Assembly Speed: Aluminum profiles can be cut to length and bolted together using simple hand tools. No "hot work" permits are needed. A frame that takes two days to weld and paint can often be assembled in aluminum in three hours.

Logistics: Because aluminum is lighter, shipping costs for raw materials and finished assemblies are reduced. The material is also easier to handle manually, reducing the need for heavy cranes or forklifts during installation.

Modularity: This is the long-term ROI factor. If a manufacturing line changes, a welded steel structure is often scrapped. An aluminum structure can be disassembled, and the profiles reused for the new layout. This reusability makes aluminum an asset rather than a consumable.

Environmental and Operational Resistances

Industrial environments are harsh. Moisture, chemicals, and temperature fluctuations attack structural materials constantly. Choosing the wrong material can lead to premature failure and contamination issues.

Corrosion Resistance

Steel contains iron, which oxidizes into rust (iron oxide) when exposed to moisture and oxygen. This rust flakes off, exposing more fresh metal to corrosion, eventually eating through the structure. To prevent this, steel requires constant maintenance of its paint or coating.

Aluminum naturally forms a microscopic, hard oxide layer that protects the underlying metal. This layer does not flake; it seals the surface. Furthermore, most industrial extrusions are anodized—an electrochemical process that thickens this protective layer and hardens the surface. For industries like food processing, pharmaceuticals, or outdoor infrastructure, aluminum eliminates the risk of rust contamination and the need for repetitive painting.

Thermal Performance

Temperature affects these metals differently. Aluminum has a higher coefficient of thermal expansion than steel, meaning it will expand and contract more as temperatures fluctuate. In precision applications spanning long distances, this expansion must be calculated to prevent warping.

However, aluminum is also an excellent conductor of heat. In electronics and LED manufacturing, aluminum structural members often double as heatsinks, dissipating heat away from sensitive components. Steel acts as a thermal insulator, holding heat in, which can be detrimental in high-temperature operating environments.

Maintenance Requirements

Consider the long-term maintenance cycle. A steel structure outdoors may need scraping and repainting every few years. An anodized aluminum structure generally requires only a periodic wash-down to remove surface dirt. Over a 10 or 20-year lifespan, the elimination of maintenance labor contributes significantly to the cost savings of aluminum.

Decision Framework: When to Choose Steel vs. Aluminum Extrusion

Neither material is universally superior. The choice depends on the specific demands of your project. Use this framework to guide your decision.

Success Criteria for Steel

You should stick with steel if your application involves:

Extreme Static Loads: For building columns, heavy machinery bases (presses, stamping machines), or applications supporting tons of weight, the high modulus of steel is necessary.

Impact Risks: Heavy mobile equipment (forklifts) bumping into the structure. Steel might dent, but it survives impact better than aluminum, which might crack or deform permanently.

High Heat: If the structure is near furnaces or welding cells where temperatures exceed 200°C (400°F), aluminum loses strength rapidly.

Permanent Installations: If the structure will never move or change, the modularity of aluminum is unnecessary.

Success Criteria for Aluminum Extrusion

You should switch to aluminum extrusion if your application involves:

Precision Framing: Machine guarding, sensor mounts, and automation cells where alignment is critical.

Modularity: Lean manufacturing environments where workflows change frequently, requiring layouts to be adjusted.

Weight Sensitivity: Mobile carts, robotic arms, or aerospace tooling where every kilogram saved improves performance.

Clean Environments: Medical, pharmaceutical, or food packaging areas where paint flakes and rust are unacceptable.

Aesthetics: Showrooms, trade show displays, and modern workspaces prioritize the sleek look of anodized aluminum.

Implementation Risks and Engineering Considerations

While aluminum offers immense versatility, engineers must respect its limitations to ensure safety.

Fatigue Limits

A critical metallurgical difference is fatigue. Steel has an "endurance limit." If you keep stress loads below a certain threshold, steel can theoretically cycle infinitely without failing. Aluminum does not have a defined endurance limit. Regardless of how small the stress is, cyclic loading will eventually cause fatigue failure over time. For high-cycle vibration applications, engineers must oversize the aluminum components to ensure the lifespan exceeds the machine's intended service life.

Galvanic Corrosion

When aluminum and steel touch in the presence of an electrolyte (like humidity or salt water), galvanic corrosion occurs. The aluminum acts as an anode and corrodes rapidly to protect the steel. Best practices involve using insulating washers, plastic spacers, or stainless steel fasteners to break the electrical path between dissimilar metals.

Connection Integrity

Bolted connections are susceptible to vibration. While a welded steel joint is fused permanently, a bolted aluminum joint can loosen over time if subjected to high-frequency vibration. To mitigate this, engineers use locking washers, thread-locking compounds (like Loctite), or specialized vibration-proof fasteners. Regular inspection schedules are recommended for aluminum structures in vibrating environments.

Conclusion

The debate of whether extruded aluminum is stronger than steel is ultimately a question of application, not just metallurgy. While steel retains the crown for raw yield strength and stiffness, aluminum extrusion frequently wins on efficiency, specific strength, and versatility. By utilizing complex geometries, aluminum achieves structural rigidity that rivals steel while reducing weight and eliminating the need for welding.

When finalizing your decision, take a holistic view of the project budget. Do not look only at the price per linear foot of material. Instead, calculate the cost per finished unit, factoring in labor, finishing, shipping, and future modifications. For heavy, permanent, high-impact loads, steel remains the standard. However, for modern, adaptable, and efficient industrial environments, aluminum extrusion offers a smarter path forward.

Before ordering materials, always consult with a structural engineer to evaluate your specific load requirements and safety factors.

FAQ

Q: Is aluminum extrusion cheaper than steel?

A: Raw aluminum is more expensive per pound than steel. However, the installed cost of aluminum extrusion is often lower. This is because aluminum eliminates the costs associated with welding, painting, and heavy-lifting equipment. It also significantly reduces assembly labor time. For complex or modular projects, the Total Cost of Ownership (TCO) for aluminum is frequently superior to steel.

Q: Can aluminum replace steel in structural beams?

A: In many cases, yes, but with design adjustments. You cannot simply swap a steel beam for an aluminum one of the exact same size and expect the same stiffness. You typically need to use a larger aluminum profile or one with internal ribbing to match the rigidity of steel. For extremely high loads, such as skyscraper skeletons, steel remains the only viable option.

Q: Does aluminum rust like steel?

A: No. Aluminum does not rust. Rust is specifically iron oxide, which destroys steel. Aluminum forms aluminum oxide, a hard, protective layer that prevents further corrosion. This makes aluminum ideal for wet or humid environments where steel would require constant repainting to survive.

Q: Is 6061 aluminum as strong as mild steel?

A: Their yield strengths are surprisingly close. 6061-T6 aluminum has a yield strength of approximately 40,000 psi (276 MPa), while A36 structural steel is around 36,000 psi (250 MPa). However, steel is roughly three times stiffer (higher Modulus of Elasticity). While aluminum resists permanent bending well, it will deflect (flex) more than steel under the same load unless the profile is designed to compensate.

Q: Can you weld aluminum extrusion?

A: Yes, aluminum can be welded, but it is rarely done with modular extrusions. Welding aluminum reduces the strength of the metal in the Heat Affected Zone (HAZ) by nearly half (destroying the T6 temper). The primary advantage of T-slot extrusion is the ability to bolt it together, maintaining full material strength and allowing for future adjustments.