Are you curious about the differences between various aluminum series? Understanding the distinctions can significantly impact your project’s success. Extruded aluminum is a popular choice in many industries due to its versatility and strength. The extrusion process creates lightweight yet durable profiles suitable for countless applications. In this post, we’ll explore the key differences between 10 Series and 15 Series extruded aluminum. You’ll learn which series is best for your specific needs and how to choose the right one for your project.

Understanding Aluminum Series

When it comes to extruded aluminum, understanding the classification of aluminum series is crucial. These series are not just arbitrary numbers; they represent specific dimensions and properties that dictate how the aluminum can be used.

What Are Aluminum Series?

Aluminum series are categorized based on their dimensions and design features. The most common systems include the 10 Series and 15 Series, each tailored for different applications.

● 10 Series: Typically features a 1-inch profile. It's compact, making it ideal for lighter-duty applications. Common uses include smaller frames and enclosures.

● 15 Series: Generally offers a 1.5-inch profile. This series is designed for heavier loads and provides greater structural integrity. You'll find it in applications requiring robust support, like industrial machinery.

Explanation of the Series Classification System

The classification system helps manufacturers and engineers identify the right aluminum profile for their projects. Each series has specific characteristics:

● Dimensions: The first digit often indicates the width of the profile. For example, a 10 Series profile is 1 inch wide, while a 15 Series profile is 1.5 inches wide.

● Load Capacity: Higher series numbers typically indicate a greater load-bearing capacity. This means that as you move from the 10 Series to the 15 Series, you can expect improved strength and stability.

● Slot Configuration: Each series has unique slot designs that accommodate various accessories and fasteners. The 10 Series may have fewer slots, while the 15 Series allows for larger, more robust attachments.

Series | Profile Width | Load Capacity | Common Applications |

10 | 1 inch | Light | Small frames, enclosures |

15 | 1.5 inches | Heavy | Industrial machinery, workstations |

Importance of Series in Determining Application Suitability

Choosing the right aluminum series is essential for ensuring that your project is both functional and cost-effective. Here’s why it matters:

● Performance: Using the appropriate series ensures that your structure can handle the intended loads. For instance, selecting a 15 Series for a heavy-duty application prevents structural failure.

● Compatibility: Each series is designed to work with specific accessories. If you choose a 10 Series but need the strength of a 15 Series, you might struggle to find compatible brackets or fasteners.

● Cost Efficiency: While the 10 Series is more economical for lighter applications, the 15 Series provides long-term savings by reducing the need for frequent repairs or replacements in demanding environments.

In summary, understanding the differences between aluminum series is key to making informed decisions in your projects. By selecting the right series, you can optimize performance, enhance compatibility, and achieve cost efficiency in your use of extruded aluminum.

Overview of 10 Series Extruded Aluminum

When we talk about extruded aluminum, the 10 Series stands out for its unique features and versatility. This series is specifically designed to meet the needs of lighter-duty applications, making it a popular choice in various industries.

What is 10 Series Extruded Aluminum?

10 Series extruded aluminum profiles are characterized by their compact dimensions, typically measuring 1 inch in width. This size is perfect for projects where space is limited but strength is still necessary.

● Dimensions and Specifications:

○ Width: 1 inch (25.4 mm)

○ Height: Varies depending on the profile design

○ Slot configurations: Typically features smaller slots for lighter attachments

These specifications allow for a range of applications, from small enclosures to intricate frames. The lightweight nature of 10 Series extrusions makes them easy to handle and install.

● Typical Applications and Use Cases:

○ Small machinery frames

○ DIY projects and hobbyist applications

○ Light-duty workstations

○ Enclosures for electronics or equipment

Advantages of 10 Series Extrusions

Choosing 10 Series extrusions comes with several benefits that make them an attractive option for many projects.

● Compact Profile Benefits: The 1-inch width allows for a sleek design without sacrificing strength. This compactness is ideal for applications where aesthetics matter, such as in consumer products or visible structural elements.

● Cost-Effectiveness for Lighter-Duty Applications: 10 Series aluminum profiles are generally more affordable than their heavier counterparts. This cost-effectiveness makes them suitable for budget-conscious projects while still providing adequate performance.

● Ideal for Smaller Frames and Enclosures: These extrusions excel in applications that require smaller frames. Their lightweight nature makes them easy to integrate into various designs, whether for prototyping or final products.

Feature | 10 Series Extruded Aluminum |

Width | 1 inch (25.4 mm) |

Load Capacity | Light-duty |

Common Uses | Small frames, enclosures |

Cost | Economical |

In summary, the 10 Series extruded aluminum profiles are a versatile choice for lighter applications. Their compact design, affordability, and suitability for small-scale projects make them a go-to option for engineers and designers alike. Whether you’re working on a small machine or a DIY project, the 10 Series can provide the strength and efficiency you need.

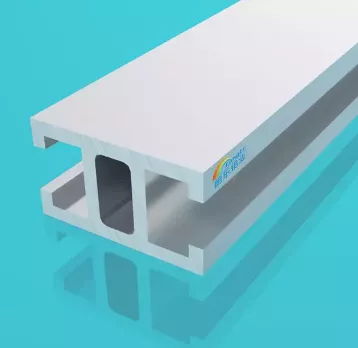

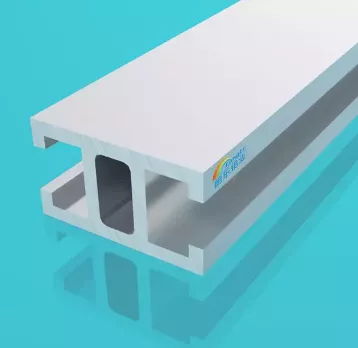

Overview of 15 Series Extruded Aluminum

When discussing extruded aluminum, the 15 Series is recognized for its strength and versatility. This series is designed to handle heavier loads and is often the go-to choice for demanding applications.

What is 15 Series Extruded Aluminum?

The 15 Series extruded aluminum profiles typically feature a width of 1.5 inches. This increase in size compared to the 10 Series allows for greater structural support and durability.

● Dimensions and Specifications:

○ Width: 1.5 inches (38.1 mm)

○ Height: Varies based on specific profile design

○ Slot configurations: Designed for larger accessories and fasteners

This series is engineered to meet the requirements of more robust applications, making it ideal for industrial settings.

● Typical Applications and Use Cases:

○ Heavy-duty machinery frames

○ Workstations and assembly lines

○ Structural supports in construction

○ Racking systems for warehouses

Advantages of 15 Series Extrusions

Choosing 15 Series extrusions offers several significant benefits, particularly for projects requiring strength and reliability.

● Enhanced Load-Bearing Capacity: The larger dimensions of the 15 Series allow it to support heavier loads. This is crucial in environments where safety and performance are paramount.

● Structural Integrity for Heavy-Duty Applications: With its robust design, the 15 Series provides exceptional structural integrity. It can withstand the rigors of demanding operations, making it suitable for industrial machinery and equipment.

● Compatibility with Larger Fasteners and Accessories: The 15 Series profiles are designed to accommodate larger fasteners and accessories, enhancing their versatility. This compatibility simplifies assembly and allows for more complex designs.

Feature | 15 Series Extruded Aluminum |

Width | 1.5 inches (38.1 mm) |

Load Capacity | Heavy-duty |

Common Uses | Machinery frames, racking |

Cost | Higher than 10 Series |

In summary, the 15 Series extruded aluminum profiles are tailored for heavy-duty applications. Their enhanced load-bearing capacity, structural integrity, and compatibility with larger accessories make them a reliable choice for industries needing robust solutions. Whether it's for machinery or construction, the 15 Series delivers the performance necessary for demanding tasks.

Key Differences Between 10 Series and 15 Series Extruded Aluminum

When considering extruded aluminum, the differences between the 10 Series and 15 Series are crucial for selecting the right profile for your project. Each series has its unique characteristics that cater to different needs.

Profile Size and Shape

One of the most noticeable differences lies in the dimensions and shape of the profiles.

● 10 Series: Typically features a 1-inch width, making it compact and suitable for lighter applications. The slot configurations are designed for smaller fasteners, which limits the load-bearing capabilities.

● 15 Series: Offers a wider profile at 1.5 inches. This increased width enhances structural integrity and allows for larger slot configurations. The slots in the 15 Series are designed to accommodate bigger fasteners, providing more flexibility in assembly.

Series | Profile Width | Slot Size |

10 | 1 inch | Smaller |

15 | 1.5 inches | Larger |

Load Capacity and Strength

Load capacity is another critical factor where these two series differ significantly.

● 10 Series: Designed for light-duty applications, it can handle moderate loads but is not suitable for heavy industrial use. Its lighter construction is ideal for projects like small frames and enclosures.

● 15 Series: Built for heavy-duty applications, it has a much higher load-bearing capacity. This series is perfect for machinery frames and structural supports where strength is essential.

Use Cases and Applications

Understanding the specific applications for each series can help you make an informed choice.

● 10 Series Applications:

○ Small machinery and equipment

○ DIY projects and home improvement tasks

○ Lightweight frames and enclosures

● 15 Series Applications:

○ Industrial machinery and equipment

○ Heavy-duty workstations and assembly lines

○ Structural supports in construction and racking systems

Accessories and Compatibility

The compatibility of accessories is vital when working with extruded aluminum profiles.

● 10 Series Compatibility:

○ Designed for smaller brackets and fasteners.

○ Ideal for lightweight accessories that require less support.

● 15 Series Compatibility:

○ Accommodates larger brackets, fasteners, and connectors.

○ Offers more options for complex assemblies and heavy-duty applications.

Using the right series is essential for ensuring that your accessories fit properly and perform as intended. Choosing the wrong series can lead to structural issues and increased costs down the line.

In summary, understanding these key differences between the 10 Series and 15 Series extruded aluminum will help you select the best profile for your specific needs. Whether you require lightweight solutions or robust support, knowing the right series makes all the difference in your project's success.

Choosing the Right Series for Your Project

Selecting the appropriate extruded aluminum series for your project can significantly impact its success. The choice between the 10 Series and 15 Series hinges on several factors that you should carefully consider.

Factors to Consider When Choosing Between 10 Series and 15 Series

When evaluating which series to use, think about the following elements:

● Project Requirements:

○ Space: If your project has limited space, the 10 Series, with its compact profile, might be ideal. However, if you need additional strength and support, the 15 Series offers a wider profile that can accommodate larger loads.

○ Load: Assess the weight your structure needs to support. The 10 Series is suitable for light-duty applications, while the 15 Series is designed for heavy-duty use.

○ Design Complexity: More complex designs may benefit from the flexibility of the 15 Series, which allows for larger fasteners and accessories.

● Cost Considerations and Budget Constraints:

○ The 10 Series is generally more cost-effective, making it a great choice for projects with tight budgets. However, investing in the 15 Series may save you money in the long run if your application requires greater durability and strength.

Common Mistakes to Avoid

Making the right choice is crucial, but avoiding common pitfalls is equally important.

● Misjudging Load Requirements: Underestimating the load your project will need to support can lead to structural failure. Always calculate the expected loads accurately to choose the appropriate series.

● Ignoring Compatibility with Accessories: Each series has specific accessory compatibility. Using the wrong series can lead to issues during assembly, resulting in delays and increased costs. Ensure that your chosen series aligns with the brackets, fasteners, and connectors you plan to use.

● Not Considering Future Scalability and Adaptability: It’s easy to focus solely on current needs, but consider how your project might evolve. The 15 Series offers greater adaptability for future modifications or expansions, making it a wise choice for projects that may grow over time.

Factor | 10 Series | 15 Series |

Space | Compact profile | Wider profile |

Load Capacity | Light-duty | Heavy-duty |

Cost | More economical | Higher initial investment |

Accessory Compatibility | Smaller fasteners | Larger fasteners |

By taking these factors into account and avoiding common mistakes, you can make a more informed decision about whether the 10 Series or 15 Series extruded aluminum is the right fit for your project. It’s all about aligning your specific requirements with the strengths of each series to ensure optimal performance and longevity.

Practical Applications of 10 Series and 15 Series Extruded Aluminum

Understanding the practical applications of 10 Series and 15 Series extruded aluminum helps you see how each series fits into various projects. Both offer unique advantages tailored to specific needs, making them valuable in different contexts.

Real-World Examples of 10 Series Applications

The 10 Series excels in lighter-duty applications, making it a popular choice for many DIY enthusiasts and small-scale projects.

● Case Studies or Scenarios:

○ Home Improvement Projects: Many homeowners use 10 Series extrusions to build custom shelving units. The lightweight nature allows for easy installation and adjustment, making it perfect for organizing tools or displaying decorative items.

○ Hobbyist Applications: In the world of robotics, hobbyists often turn to 10 Series for building lightweight frames. The ability to create custom structures without excessive weight is a huge advantage for mobile robots.

● Examples in DIY Projects and Light Machinery:

○ Small Furniture: The 10 Series is ideal for constructing lightweight furniture such as desks and chairs. Its compact size allows for sleek designs while maintaining structural integrity.

○ Light Machinery Frames: Small-scale machinery, like 3D printers, frequently utilizes 10 Series profiles. The strength-to-weight ratio is perfect for ensuring stability without adding unnecessary bulk.

Application Type | Examples | Benefits |

Home Improvement | Custom shelving units | Easy installation |

Robotics | Lightweight frames | Mobility and customization |

Small Furniture | Desks and chairs | Sleek design and stability |

Light Machinery | 3D printer frames | Strength without bulk |

Real-World Examples of 15 Series Applications

The 15 Series is designed for heavy-duty applications, making it the go-to choice for industrial settings and demanding environments.

● Case Studies or Scenarios:

○ Industrial Frameworks: Many factories use 15 Series extrusions for building robust conveyor systems. The enhanced load-bearing capacity ensures that heavy materials can be transported safely and efficiently.

○ Heavy-Duty Machinery: In construction, the 15 Series is utilized for creating frames for large equipment. This includes everything from scaffolding to support structures for cranes, where strength is critical.

● Examples in Industrial Frameworks and Heavy-Duty Machinery:

○ Racking Systems: Warehouses often implement 15 Series profiles for racking systems due to their ability to support significant weight. This ensures safe storage of heavy goods without compromising stability.

○ Assembly Lines: Manufacturing facilities frequently use the 15 Series to create assembly line frameworks. The durability and adaptability of these profiles allow for efficient workflow management.

Application Type | Examples | Benefits |

Industrial Frameworks | Conveyor systems | Safe and efficient transport |

Heavy-Duty Machinery | Equipment frames | Critical strength |

Racking Systems | Warehouse storage | Safe storage of heavy goods |

Assembly Lines | Manufacturing frameworks | Efficient workflow management |

Both the 10 Series and 15 Series extruded aluminum profiles have distinct advantages that cater to different project requirements. By understanding these practical applications, you can make informed decisions on which series best fits your needs, ensuring optimal performance and reliability in your projects.

Conclusion

This article highlights the key differences between 10 Series and 15 Series extruded aluminum. The 10 Series is ideal for light-duty applications, while the 15 Series suits heavy-duty needs. Choosing the right series is crucial for project success. Langle offers high-quality extruded aluminum products that provide exceptional strength and versatility. Their commitment to customer satisfaction ensures you find the perfect solution for your needs.

FAQ

Q: What is the main difference between 10 Series and 15 Series extruded aluminum?

A: The primary difference lies in their dimensions and load capacities. The 10 Series is lighter and suited for smaller applications, while the 15 Series offers greater strength for heavy-duty uses.

Q: How do I choose the right series of extruded aluminum for my project?

A: Consider factors like load requirements, space constraints, and design complexity. The 10 Series works well for light projects, while the 15 Series is ideal for heavier applications.

Q: Why is extruded aluminum popular in construction?

A: Extruded aluminum is favored for its lightweight yet durable properties, making it suitable for various structural applications, from frames to supports.

Q: What are the cost differences between 10 Series and 15 Series extruded aluminum?

A: Generally, the 10 Series is more cost-effective, while the 15 Series may have a higher initial cost due to its enhanced load-bearing capabilities.

Q: Can I use accessories designed for 10 Series with 15 Series extruded aluminum?

A: No, each series has specific compatibility. Using the right accessories ensures optimal performance and safety in your projects.