Introduction

Aluminum extrusion is a pivotal process in modern manufacturing, enabling the creation of complex cross-sectional profiles that are integral to various industries, including automotive, aerospace, construction, and electronics. This process involves pushing heated aluminum billet through a die to produce components with specific shapes and features. While Aluminum Extrusion offers numerous advantages such as design flexibility, lightweight characteristics, and cost-effectiveness for large production runs, it is not without its disadvantages. A comprehensive understanding of these drawbacks is essential for engineers and decision-makers when selecting the most appropriate manufacturing method for their applications. This article delves into the inherent disadvantages of aluminum extrusion, providing a critical analysis that encompasses mechanical limitations, design constraints, surface finish issues, and environmental considerations.

Mechanical Property Limitations

One of the foremost disadvantages of aluminum extrusion pertains to the mechanical properties of the resulting products. Aluminum alloys, while offering an excellent strength-to-weight ratio, generally possess lower tensile strength and hardness compared to ferrous metals such as steel. For instance, common extrudable aluminum alloys like 6061-T6 exhibit a tensile strength of approximately 290 MPa, whereas structural steel (A36) can reach up to 400 MPa. This inherent limitation restricts the use of extruded aluminum components in applications requiring high-load bearing capacity or where structural rigidity is paramount.

Furthermore, the extrusion process can introduce anisotropy in mechanical properties due to the alignment of grain structures along the extrusion direction. This means that the material may exhibit different strength and ductility characteristics in longitudinal versus transverse directions. Such anisotropy can lead to unexpected performance issues under multi-directional loading conditions, compromising the integrity of the component in critical applications.

Additionally, extruded aluminum components may suffer from fatigue limitations. Aluminum alloys do not exhibit a well-defined fatigue limit like some steels, meaning they can fail under cyclic loading even at low stress levels over time. This characteristic necessitates meticulous design considerations and may limit the use of extruded aluminum in applications subjected to repetitive stress cycles, such as in aerospace structures or automotive components.

Dimensional Constraints and Tolerance Challenges

While aluminum extrusion allows for the creation of intricate profiles, there are inherent dimensional constraints imposed by the process. The size of the extrusion press and the capacity of the dies limit the maximum cross-sectional dimensions and length of extruded products. Large-scale components may require joining multiple extrusions, introducing potential weak points and increasing assembly complexity.

Moreover, maintaining tight tolerances can be challenging due to factors such as thermal expansion, die wear, and variations in material flow during extrusion. Achieving precise dimensions often necessitates additional machining operations post-extrusion, which can increase production time and costs. These tolerance challenges are particularly critical in industries where precision is vital, such as in the manufacture of electronic enclosures or medical devices.

Furthermore, the control of wall thickness in hollow or semi-hollow profiles can be problematic. Uneven material flow can result in non-uniform wall thickness, affecting the structural performance and leading to potential failure points under load. Manufacturers must employ advanced die design and process control techniques to mitigate these issues, which can add to the complexity and cost of production.

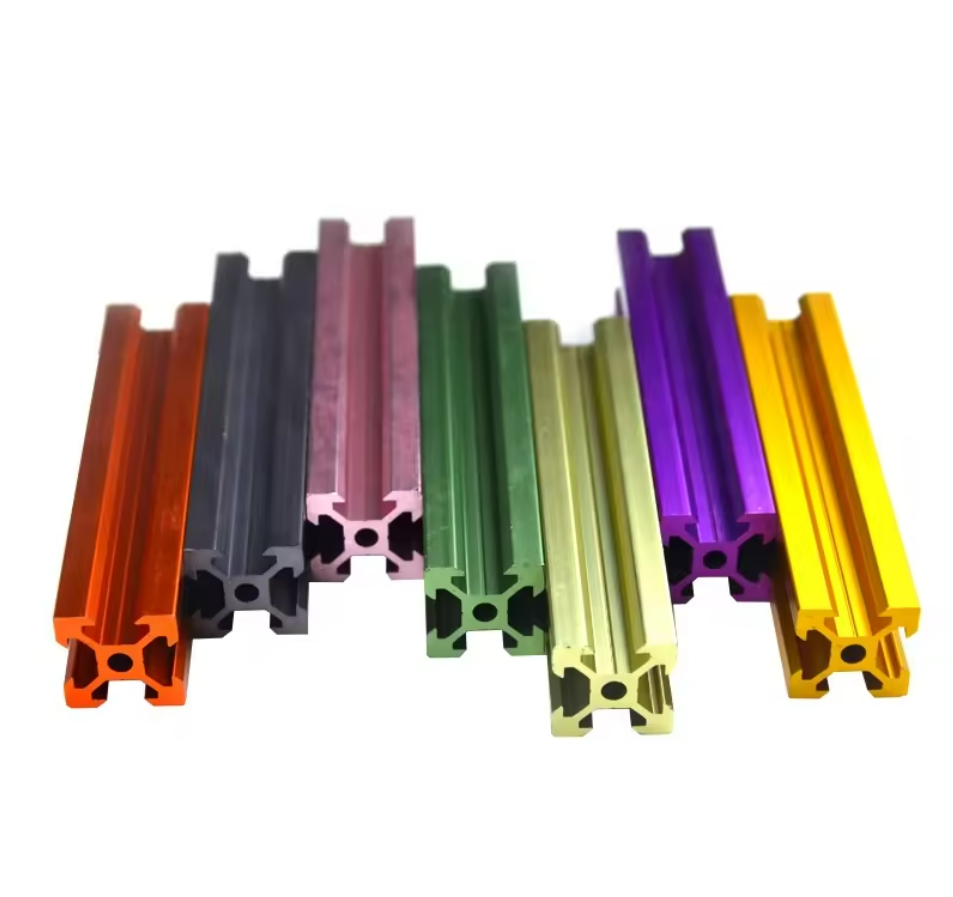

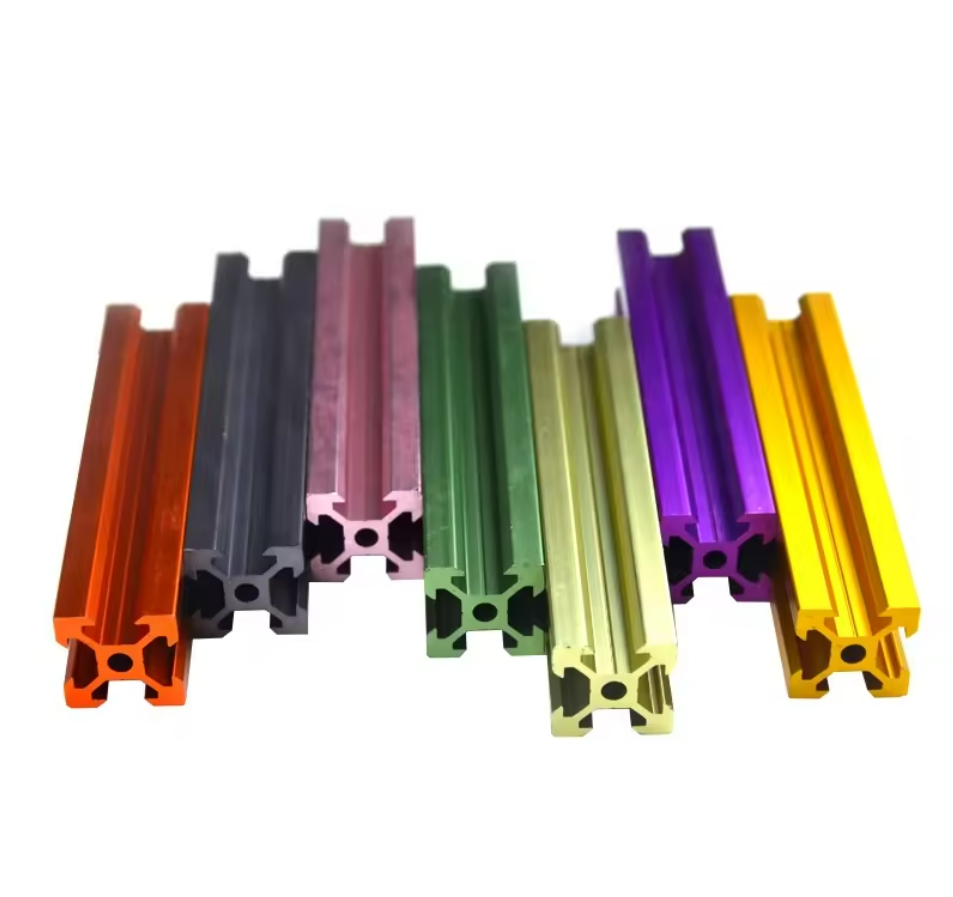

Surface Finish Limitations

The surface quality of extruded aluminum profiles is another area where disadvantages manifest. The extrusion process can introduce surface imperfections such as die lines, scratches, or rough textures due to the interaction between the aluminum and the die surfaces. These surface defects can be detrimental in applications where aesthetics are important or where surface finish affects functionality, such as in reflective surfaces or sealing interfaces.

Achieving a high-quality surface finish often requires additional finishing processes like sanding, polishing, or anodizing. These steps not only increase the production time but also add to the overall cost. In some cases, the surface imperfections may be severe enough that they cannot be economically remedied, limiting the use of extrusion for certain high-finish applications.

Moreover, surface defects can act as initiation sites for corrosion or fatigue cracks, potentially reducing the lifespan of the component. Protective coatings and treatments can mitigate these risks but involve further processing. Understanding these limitations is crucial when specifying extruded components for environments where corrosion resistance and longevity are critical.

Design and Geometry Limitations

While aluminum extrusion is celebrated for its ability to produce complex cross-sectional geometries, there are still design limitations that must be considered. Certain features, such as sharp internal corners, undercuts, or very thin walls, may not be feasible due to die design constraints and material flow characteristics during extrusion.

The necessity to maintain uniform material flow often requires designers to compromise on the ideal geometry of the component. This can result in parts that are heavier or bulkier than desired, potentially impacting the performance or efficiency of the final product. In some cases, achieving the required design may only be possible through alternative manufacturing methods like Aluminum Extrusion, which can accommodate more intricate geometries but at a higher cost.

Moreover, modifications to an existing design can be costly and time-consuming since they may require the fabrication of new dies. This inflexibility can hinder rapid prototyping or iterative design processes that are common in today's fast-paced development cycles. Engineers must weigh these constraints during the design phase to ensure that extrusion is the most suitable manufacturing method for their application.

Initial Tooling and Production Costs

The upfront costs associated with aluminum extrusion can be significant, especially for custom profiles. Designing and manufacturing extrusion dies require specialized expertise and equipment, leading to high initial investment. For small production runs or prototypes, these costs may not be justifiable, making extrusion less attractive compared to other manufacturing methods such as machining or additive manufacturing.

Additionally, lead times for die fabrication and process setup can be lengthy, potentially delaying project timelines. This factor can be critical in industries where time-to-market is a competitive advantage. Companies must consider the balance between the economies of scale offered by extrusion for large quantities and the financial implications for smaller production volumes.

Furthermore, any design changes after the initial tooling has been produced can incur additional costs and delays. The inflexibility in accommodating design iterations adds a layer of risk for projects that are still in the development phase or may require customization.

Environmental and Energy Considerations

The energy-intensive nature of the aluminum extrusion process is another disadvantage that has environmental implications. Heating the aluminum billet to the necessary temperatures for extrusion consumes a considerable amount of energy. When this energy is derived from fossil fuels, it contributes to greenhouse gas emissions and environmental degradation.

Moreover, although aluminum is highly recyclable, the recycling process itself requires significant energy input. While recycling aluminum scrap reduces the need for primary aluminum production from bauxite ore, it does not eliminate the environmental footprint associated with the extrusion process. Companies focused on sustainability may find these factors at odds with their environmental goals.

Efforts to mitigate these impacts include investing in energy-efficient technologies, utilizing renewable energy sources, and optimizing process efficiency. However, these initiatives may involve substantial capital expenditures and are not always feasible for all manufacturers. Understanding the environmental disadvantages is crucial for organizations aiming to minimize their ecological footprint through responsible manufacturing practices.

Thermal Conductivity and Heat Treatment Challenges

Aluminum's high thermal conductivity can present challenges during the extrusion process and in service. The rapid dissipation of heat can lead to uneven cooling rates, resulting in residual stresses and distortion within the extruded components. These stresses may cause warping or dimensional inaccuracies, necessitating corrective measures post-extrusion.

In applications where thermal stability is critical, such as in precision instruments or aerospace components, these distortions can compromise functionality and safety. Additional heat treatment processes, such as stress relieving or annealing, may be required to stabilize the material, adding complexity and cost to the manufacturing process.

Furthermore, the heat treatment of aluminum alloys must be carefully controlled to achieve desired mechanical properties. Variations in cooling rates or furnace temperatures can lead to inconsistent results, affecting the performance of the final product. Manufacturers must employ stringent quality control measures to ensure uniformity, which can increase operational costs.

Corrosion Susceptibility

While aluminum exhibits a natural oxide layer that provides a degree of corrosion resistance, it is not immune to degradation in certain environments. Exposure to chlorides, such as in marine atmospheres or de-icing salts, can lead to pitting corrosion or stress corrosion cracking. Extruded aluminum components used in such environments may require protective coatings or alloys with enhanced corrosion resistance, which can add to the material and processing costs.

Additionally, galvanic corrosion can occur when aluminum is in contact with more noble metals like copper or steel in the presence of an electrolyte. This phenomenon can lead to accelerated corrosion of the aluminum component, compromising its structural integrity. Design strategies must include measures to prevent galvanic coupling, such as insulation or the use of compatible materials, adding complexity to the engineering process.

Conclusion

In conclusion, aluminum extrusion is a versatile manufacturing process that offers significant benefits but also comes with notable disadvantages. Limitations in mechanical properties, design constraints, surface finish challenges, and environmental considerations must be carefully evaluated during the material and process selection phases. Understanding these drawbacks enables engineers and manufacturers to make informed decisions, potentially opting for alternative methods when the disadvantages outweigh the advantages.

Advancements in technology and processes continue to mitigate some of these disadvantages, such as through the development of high-strength aluminum alloys or more efficient extrusion techniques. However, a thorough analysis of the specific application requirements is essential. For industries seeking solutions that balance performance and cost, exploring innovations in Aluminum Extrusion remains a worthwhile endeavor. The future of manufacturing will undoubtedly continue to integrate aluminum extrusion where its strengths are maximized and its weaknesses are effectively managed.

"}