Introduction

Aluminum is a versatile metal widely used in various industries due to its lightweight and corrosion-resistant properties. However, the term \"extruded aluminum\" often comes up in manufacturing and engineering contexts, leading to confusion about its relationship to standard aluminum. This article aims to delve into the differences between aluminum and extruded aluminum, exploring their properties, production processes, and applications. Understanding these differences is crucial for material scientists and engineers when selecting the appropriate material for specific applications. By examining the nuances between the two, we can appreciate how Aluminum Extrusion contributes to modern manufacturing.

Fundamentals of Aluminum

Aluminum, represented by the symbol Al and atomic number 13, is the third most abundant element in the Earth's crust. Its low density and ability to resist corrosion through passivation make it an ideal material for various applications. Aluminum's properties include high thermal and electrical conductivity, malleability, and ductility. These characteristics make it suitable for products ranging from household foil to aircraft components.

In its pure form, aluminum is soft and lacks strength. Therefore, it is often alloyed with elements like copper, magnesium, silicon, and zinc to enhance its mechanical properties. These alloys are categorized into different series based on their alloying elements and are used in applications that require specific strength and durability profiles.

Understanding Extruded Aluminum

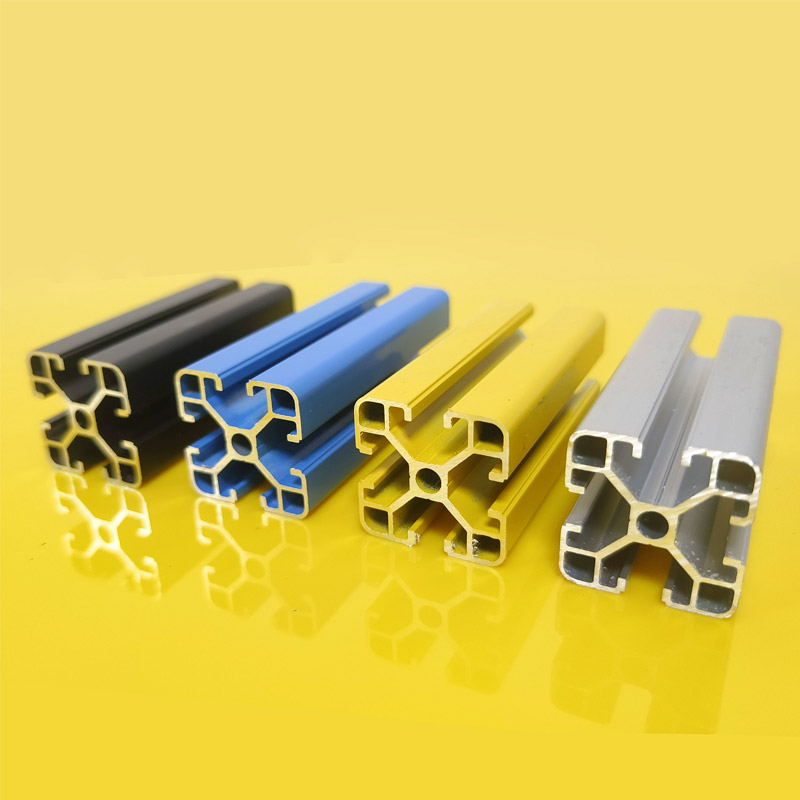

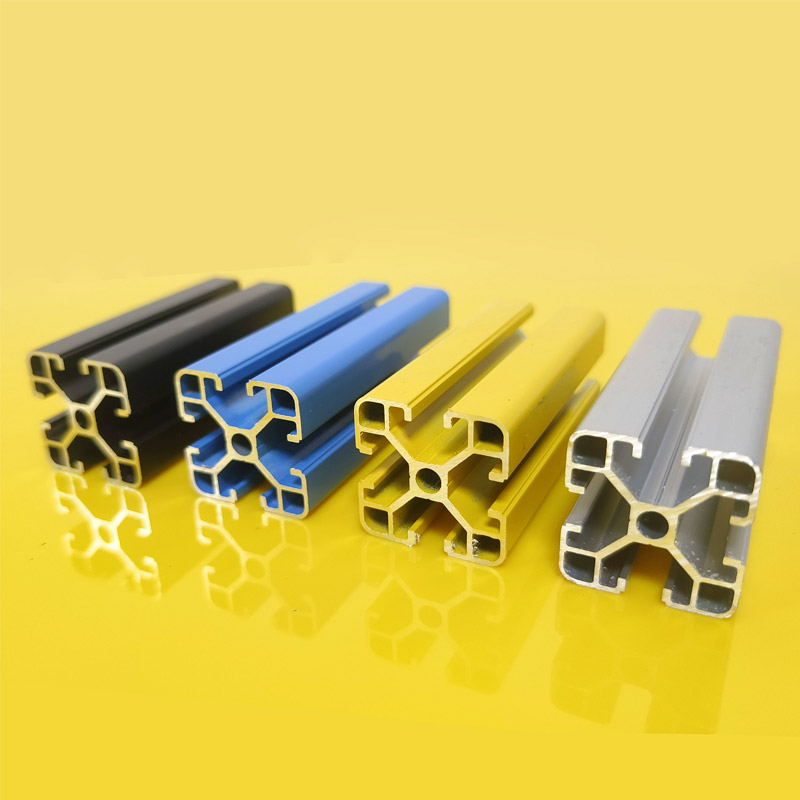

Extruded aluminum refers to aluminum that has undergone the extrusion process, a technique used to transform aluminum alloy into objects with a fixed cross-sectional profile. This process allows for the creation of complex shapes with excellent surface finish and dimensional accuracy. Extruded aluminum is widely used in construction, automotive, aerospace, and consumer goods industries due to its enhanced mechanical properties and design flexibility.

The extrusion process involves forcing heated aluminum billets through a die of the desired cross-section. The combination of heat and pressure alters the aluminum's microstructure, resulting in improved strength along the extrusion axis. This process not only improves mechanical properties but also allows for the efficient production of components with intricate designs.

The Extrusion Process in Detail

The aluminum extrusion process can be broken down into several key stages:

Billet Preparation: Aluminum billets are heated to a temperature between 750°F and 925°F to soften the metal without melting it.

Extrusion: The heated billet is placed into an extrusion press container and forced through a die by a ram. The die shapes the aluminum into the desired profile.

Cooling: The extruded aluminum emerges from the die and is cooled using air, water, or a combination of both to solidify the shape.

Stretching: The extrusions are stretched to straighten and correct any twisting that occurred during extrusion.

Cutting and Aging: The extrusions are cut to length and may undergo aging, a heat treatment process that hardens the aluminum.

This process results in a material that is strong, lightweight, and can be formed into complex shapes, making extruded aluminum an essential material in modern engineering and construction.

Key Differences Between Aluminum and Extruded Aluminum

While aluminum refers to the raw metal or its alloys, extruded aluminum specifically denotes products made through the extrusion process. The primary differences between the two lie in their mechanical properties, manufacturing processes, and applications.

Mechanical Properties

The extrusion process enhances the mechanical properties of aluminum. Extruded aluminum exhibits improved tensile strength and yield strength along the extrusion direction due to the alignment of the metal's grain structure caused by the extrusion forces. This makes extruded aluminum profiles stronger and more suitable for structural applications compared to regular aluminum forms like castings or sheets.

Manufacturing Processes

Standard aluminum products are manufactured using various processes such as casting, rolling, or forging. Casting involves pouring molten aluminum into molds, rolling produces sheets and foils by passing aluminum between rollers, and forging shapes aluminum using compressive forces. In contrast, extruded aluminum is produced by pushing heated aluminum billets through dies, allowing for the creation of complex cross-sectional profiles not achievable through other manufacturing methods.

Applications

Because of the differences in manufacturing processes and mechanical properties, aluminum and extruded aluminum are used in different applications:

Aluminum Sheets and Plates: Used in packaging, automotive body panels, and aircraft skins due to their formability and surface properties.

Cast Aluminum: Common in engine blocks, housings, and components requiring complex shapes and moderate strength.

Extruded Aluminum: Ideal for structural components such as frames, beams, and supports where strength and lightweight are critical. The ability to create customized profiles makes it invaluable in industries like aerospace, automotive, and construction.

Advantages of Extruded Aluminum

Extruded aluminum offers several advantages over standard aluminum forms:

Design Flexibility

The extrusion process allows engineers to design profiles with intricate shapes, including hollow sections and complex cross-sections. This flexibility enables the integration of multiple functions into a single profile, reducing the need for additional parts and simplifying assembly processes.

Material Efficiency

Extrusion maximizes material usage by producing profiles that closely match the final component shape, minimizing waste. The process is highly efficient, making it cost-effective for large production runs and custom designs.

Enhanced Mechanical Properties

As previously mentioned, the extrusion process improves the mechanical properties of aluminum. The oriented grain structure along the extrusion axis results in better tensile strength and fatigue resistance, which are crucial in load-bearing applications.

Case Studies and Applications

To illustrate the practical applications of extruded aluminum, consider the following examples:

Automotive Industry

In the automotive sector, extruded aluminum components are used to reduce vehicle weight, contributing to improved fuel efficiency and reduced emissions. Components such as bumper beams, chassis frames, and engine cradles benefit from the strength-to-weight ratio of extruded aluminum.

Aerospace Applications

The aerospace industry utilizes extruded aluminum for structural airframe components, including wing stringers and fuselage frames. The lightweight yet strong nature of extruded aluminum is essential for meeting the performance and safety standards required in aircraft design.

Construction and Architecture

Extruded aluminum profiles are prevalent in construction for window frames, curtain walls, and structural glazing systems. Their resistance to corrosion and ability to be fabricated into aesthetically pleasing designs make them ideal for modern architectural applications.

Advancements in Aluminum Extrusion Technology

Recent technological advancements have further enhanced the capabilities of aluminum extrusion. Developments in die design, process control, and alloy formulations have expanded the range of achievable profiles and improved the quality of extrusions.

Precision Extrusion

Modern extrusion techniques allow for tighter tolerances and more precise dimensions, which is essential in industries where exact specifications are critical. Precision extrusion reduces the need for post-processing and machining, saving time and resources.

Aluminum Alloys for Extrusion

The development of new aluminum alloys tailored for extrusion has enabled manufacturers to produce profiles with enhanced properties such as increased strength, improved corrosion resistance, and better formability. Alloys from the 6xxx series, containing magnesium and silicon, are commonly used due to their excellent extrudability and mechanical properties.

Environmental Considerations

Aluminum extrusion is also recognized for its environmental benefits. Aluminum is highly recyclable, and the extrusion process requires less energy compared to producing primary aluminum from bauxite ore. Recycling aluminum consumes only about 5% of the energy required for primary production, significantly reducing the carbon footprint.

Furthermore, the use of extruded aluminum in applications like automotive and aerospace contributes to overall energy savings during the product's lifecycle by reducing weight and improving fuel efficiency.

Challenges and Future Directions

Despite its advantages, aluminum extrusion faces challenges such as the initial cost of die fabrication and limitations in producing extremely large cross-sections. Ongoing research aims to address these issues by developing cost-effective die materials and exploring new extrusion techniques like hydrostatic and equal-channel angular pressing.

The future of aluminum extrusion lies in continued innovation to improve process efficiency, material properties, and expand its applicability. With the rise of additive manufacturing and hybrid fabrication methods, extruded aluminum is expected to integrate with these technologies to produce advanced engineering solutions.

Conclusion

In summary, the difference between aluminum and extruded aluminum is primarily in the processing method and resultant properties. While aluminum serves as the base metal, extrusion transforms it into versatile profiles with enhanced mechanical characteristics suitable for a wide range of industrial applications. The extrusion process unlocks the potential of aluminum alloys, making Aluminum Extrusion an indispensable technique in modern manufacturing.

Understanding these differences is essential for engineers, manufacturers, and material scientists when selecting materials for design and construction. As technology advances, extruded aluminum is poised to play an even more significant role in developing innovative solutions that meet the demands of a growing and evolving global market.

"}