Anodized aluminum is known for its durability, but does it rust? Many people believe it’s immune to corrosion, but that’s not always the case.

In this article, we’ll explore how anodized aluminum resists rust and why it's important to understand its limits.

You’ll learn the truth behind anodized aluminum’s corrosion resistance and how to maintain it in different environments.

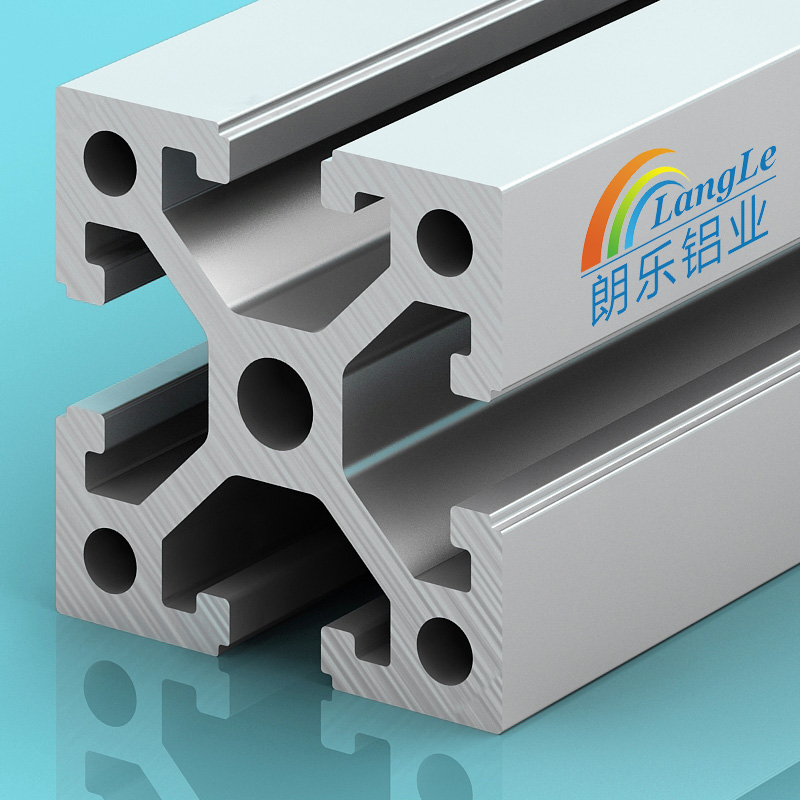

Understanding the Anodizing Process

Anodizing is an electrochemical treatment that thickens the natural oxide layer on metals like aluminum. This process differs from other treatments, such as painting or coating, because it creates a hard, durable layer directly on the metal surface, not just on top of it.

During anodizing, aluminum is submerged in an acid bath, and an electrical current is passed through. This current causes the aluminum to oxidize, forming a protective oxide layer. This process increases the metal's ability to resist wear, corrosion, and weathering.

Key Benefits of Anodizing

Increased Durability: The anodized layer makes aluminum much harder and more resistant to scratches and abrasions.

Corrosion Resistance: The oxide layer helps prevent rust and damage from exposure to air, moisture, and chemicals.

Improved Aesthetics: Anodizing can also give aluminum a bright, matte, or even colored finish, making it ideal for both functional and decorative applications.

How Anodizing Enhances Aluminum’s Properties

Anodizing does more than just coat aluminum. The process results in a tough oxide layer that bonds directly with the aluminum, enhancing its properties.

The Oxide Layer

This oxide layer forms naturally during anodizing and acts as a barrier against environmental factors. The thickness of the layer can be controlled to provide the desired level of protection and appearance.

Impact of the Oxide Layer

Surface Hardness: The oxide layer significantly increases aluminum's hardness, making it resistant to scratches and abrasions.

Corrosion Resistance: It offers protection from rust and corrosion, especially in harsh environments like marine or industrial settings.

Wear Resistance: The anodized layer also makes the aluminum more resistant to wear and tear from regular use.

Non-Conductive Nature

Another key feature of anodized aluminum is its non-conductivity. This makes it ideal for electrical and electronic applications where insulation is required. The anodized layer prevents the metal from conducting electricity, adding another layer of safety and functionality.

Does Anodized Aluminum Rust?

The Role of Oxide Layers in Rust Prevention

Anodized aluminum forms a protective oxide layer on the surface, which helps prevent rust. This oxide layer is not just a coating; it actually bonds with the aluminum, creating a hard, durable surface. It works by blocking moisture and air from reaching the underlying metal, preventing traditional rusting that happens with untreated aluminum.

How Anodizing Prevents Traditional Rusting Seen in Untreated Metals

Untreated aluminum can quickly rust when exposed to moisture and oxygen. However, when aluminum is anodized, the process forms an oxide layer that acts as a barrier, stopping corrosion before it starts. This is why anodized aluminum is more durable in outdoor environments compared to regular aluminum.

Does Anodized Aluminum Still Rust Under Certain Conditions?

Although anodized aluminum is highly resistant to rust, it's not entirely immune. Under harsh conditions, like exposure to strong acids or saltwater, the oxide layer may break down. If this layer is damaged, the aluminum underneath can be exposed to the elements, leading to corrosion over time.

Can Anodized Aluminum Rust in Harsh Environments?

Anodized aluminum performs well in most environments, but it can be affected by certain harsh conditions.

Environmental Factors That Can Affect Anodized Aluminum

Saltwater: Exposure to saltwater can cause the oxide layer to degrade, making anodized aluminum more susceptible to rust.

High Humidity: In humid climates, moisture can break down the protective layer, leading to corrosion.

Chemicals: Harsh chemicals, such as acids or cleaning agents, can damage the oxide coating over time.

Discussing Common Myths About Anodized Aluminum Rusting

Many believe that anodized aluminum cannot rust, but that's not entirely true. While anodized aluminum is more resistant to rust than untreated aluminum, it can still corrode under extreme conditions or when the oxide layer is damaged.

Situations Where Anodized Aluminum’s Oxide Layer May Degrade or Fail

Scratches or Damage: If the anodized surface is scratched or damaged, the aluminum underneath becomes exposed to air and moisture, making it prone to rust.

Harsh Chemicals: Prolonged exposure to strong chemicals or extreme environmental conditions can weaken the oxide layer, leading to corrosion.

Corrosion Resistance of Anodized Aluminum

Why Anodized Aluminum Has Better Corrosion Resistance Than Untreated Aluminum

Anodizing aluminum creates a thick oxide layer that provides much better protection against corrosion compared to untreated aluminum. The process converts the surface of the metal into a hard, non-porous oxide layer that bonds directly to the aluminum. This oxide layer acts as a shield, preventing moisture, air, and contaminants from reaching the metal surface.

Unlike untreated aluminum, which can rust quickly when exposed to moisture, anodized aluminum resists oxidation and corrosion more effectively. This makes it ideal for harsh environments like saltwater, high humidity, or industrial applications.

Case Studies or Examples in Industries That Rely on Anodized Aluminum

Aerospace: Aircraft parts exposed to high stress and extreme weather conditions benefit from anodized aluminum’s enhanced corrosion resistance.

Marine: Anodized aluminum is commonly used in boats and ships, where saltwater exposure is a major concern.

Architecture: Buildings, especially those in coastal areas, use anodized aluminum for their frames and exteriors due to its durability and resistance to environmental wear.

The Limitations of Anodized Aluminum’s Corrosion Resistance

Although anodized aluminum offers excellent corrosion protection, it is not immune to damage.

When Anodized Aluminum Might Show Signs of Wear or Corrosion

Extreme pH Environments: Strong acids or bases can break down the anodized layer, making the aluminum prone to corrosion.

Physical Damage: Scratches or other damage to the oxide layer expose the underlying aluminum, which can then corrode if exposed to moisture or air.

Why Anodized Aluminum May Need Additional Sealing or Coating for Certain Applications

In certain situations, anodized aluminum may need extra protection. For example, in harsh marine or chemical environments, sealing the anodized layer or applying an additional protective coating can further prevent corrosion. Sealing helps ensure the oxide layer remains intact, improving the overall durability of the material.

Factors That Affect Anodized Aluminum’s Rust Resistance

Environmental Conditions That Impact Anodized Aluminum

Anodized aluminum is durable, but its rust resistance can be affected by certain environmental conditions.

Saltwater Exposure: Salt can break down the oxide layer on anodized aluminum, making it more vulnerable to corrosion. This is especially important for marine applications.

Extreme Temperatures: High or low temperatures can cause the anodized surface to expand or contract. Over time, this can weaken the protective layer.

Humidity: Excess moisture in the air can also degrade the oxide layer, especially in tropical or coastal areas.

Discussing How Industrial or Chemical Environments Affect Anodized Aluminum’s Performance

Industrial and chemical environments can be harsh on anodized aluminum. Strong acids, alkalis, and chemicals like cleaners or solvents can attack the oxide layer. These conditions may lead to corrosion if the anodized layer is not properly sealed or maintained.

The Impact of Physical Damage on Anodized Aluminum

While anodized aluminum offers superior rust protection, physical damage can compromise its ability to resist corrosion.

Scratches, Dents, or Mechanical Stress: Any physical damage to the anodized surface exposes the aluminum underneath, making it susceptible to corrosion. The oxide layer is only effective as long as it remains intact.

Preventing Damage to Maintain Rust Resistance: To maintain anodized aluminum’s rust resistance, avoid impacts, scratches, or abrasive cleaning methods. Regular cleaning with non-abrasive materials and careful handling can help preserve the protective layer.

Maintaining Anodized Aluminum to Prevent Rusting

Cleaning and Care Tips for Anodized Aluminum

Proper care and cleaning are essential for maintaining anodized aluminum’s rust resistance.

Recommended Cleaning Practices: Use a soft cloth or sponge with warm water and a mild detergent to clean anodized aluminum. Avoid abrasive pads or harsh chemicals, as they can damage the oxide layer.

Frequency of Cleaning: Clean anodized aluminum surfaces regularly, especially if exposed to dust, salt, or other contaminants. For outdoor or marine environments, cleaning once a month is a good practice.

Sealing and Protecting Anodized Aluminum

To further enhance corrosion resistance, anodized aluminum can benefit from additional sealing or coating.

Additional Coatings or Sealing Processes: Applying a sealant over the anodized layer can help protect it from moisture, chemicals, and wear. Clear coatings or waxes are often used to add an extra layer of protection.

When to Apply Sealing: Sealing should be applied after anodizing, especially for aluminum in harsh environments like marine or industrial settings. This step helps ensure the oxide layer remains intact and effective in preventing rust.

Alternatives to Anodizing for Rust Prevention

Comparing Anodizing to Other Protective Coatings

Anodizing is a popular method for preventing rust on aluminum, but it’s not the only option. Other coatings, such as AL-COAT®, powder coating, and galvanization, can also provide protection against corrosion.

Powder Coating: Powder coating involves applying a dry powder to aluminum, then heating it to form a hard finish. It offers a smooth, glossy finish and good corrosion resistance, but it may not be as effective in high-temperature or high-stress environments.

Galvanization: In galvanization, aluminum is coated with a layer of zinc. This method is highly effective for rust prevention, especially in outdoor environments, but it adds weight to the material and may not be suitable for all applications.

Pros and Cons of Anodizing Versus Other Rust Prevention Methods for Aluminum

Coating Method | Pros | Cons |

Anodizing | Enhanced surface hardness, corrosion resistance, aesthetic flexibility | Not as effective in extreme environments without additional sealing |

Powder Coating | Smooth finish, cost-effective, good for most environments | Can chip or peel over time, not as durable in extreme conditions |

Galvanization | Strong protection, effective in outdoor settings | Adds weight, may affect appearance |

Each method has its strengths and is suited for different applications. When choosing the best option for rust prevention, consider factors like the environment, durability requirements, and aesthetic preferences.

Conclusion

Anodized aluminum is highly resistant to rust due to its protective oxide layer. This process significantly improves corrosion resistance compared to untreated aluminum.

While anodized aluminum offers long-lasting durability, its performance can be affected by harsh conditions or physical damage. Proper care and maintenance are essential to ensure its rust resistance over time.

Anodized aluminum remains a great choice for various applications, offering both functionality and aesthetic appeal.

FAQ

Q: Does anodized aluminum rust like regular aluminum?

A: No, anodized aluminum is more resistant to rust. The oxide layer formed during anodizing protects the metal from corrosion, unlike regular aluminum.

Q: How can I tell if anodized aluminum is rusting?

A: Signs include discoloration, peeling, or damage to the anodized layer. If the oxide layer is compromised, corrosion may occur underneath.

Q: Can anodized aluminum be restored if it starts to corrode?

A: Yes, anodized aluminum can be re-coated or polished to restore its appearance and protective properties.

Q: How long does anodized aluminum last before it shows signs of corrosion?

A: Anodized aluminum can last for decades, but its lifespan depends on environmental conditions, exposure to chemicals, and physical damage.

Q: Is anodized aluminum safe for food contact or medical uses?

A: Yes, anodized aluminum is safe for food and medical applications, as it doesn’t leach harmful chemicals and is easy to clean.