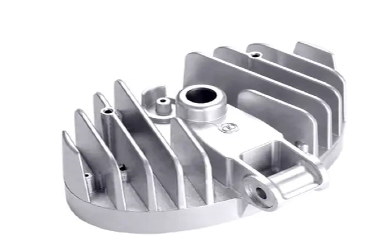

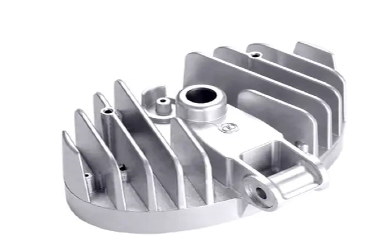

CNC milling is a highly precise and versatile manufacturing process that utilizes computer-controlled machines to cut and shape materials into desired forms. This process has revolutionized the production of parts across various industries, offering exceptional accuracy and repeatability. Among the materials commonly used in CNC milling, aluminum stands out due to its excellent machinability, lightweight properties, and resistance to corrosion. Aluminum CNC milling is particularly favored for producing complex components in aerospace, automotive, electronics, and medical devices. The precision of the CNC milling process is critical in ensuring that aluminum parts meet stringent tolerances and perform as intended. The accuracy of machining directly impacts the functionality, durability, and overall quality of the parts, making it a key factor in achieving high-performance results in production.

Factors Influencing Accuracy in Aluminum CNC Milling

1.Machine Quality:

The quality of the CNC machine is one of the most critical factors affecting milling accuracy. High-end CNC machines are equipped with advanced features such as precise servo motors, rigid construction, and robust feedback systems. These features ensure consistent and accurate movements during the milling process. Machines with superior linear guides, high-resolution encoders, and stable frames reduce vibration, minimizing errors and improving the overall precision of the parts produced. On the other hand, older or lower-quality machines might struggle to maintain the required accuracy, leading to imperfections in the finished aluminum components.

2. Tool Selection:

The choice of tools used in the CNC milling process plays a crucial role in achieving the desired accuracy. Tools made from high-quality materials, such as carbide or high-speed steel, offer better precision and longer lifespan. Additionally, tool geometry—such as the cutter’s shape, size, and cutting edge—can significantly affect the quality of the milled surface. For example, dull or improperly designed tools can cause excessive wear, leading to inaccuracies such as rough edges, uneven finishes, or dimensional errors. Selecting the right tools for specific aluminum alloys, cutting conditions, and part geometries is essential to achieving the tight tolerances required in aluminum CNC milling.

3. Material Properties:

Aluminum is a versatile and widely used material in CNC milling due to its lightweight, corrosion-resistant, and machinable nature. However, the specific alloy of aluminum being milled can affect the accuracy of the machining process. Factors such as the aluminum's hardness, surface finish, and thermal properties influence how the material responds to cutting forces. Softer aluminum alloys may allow for easier machining with higher speeds, while harder alloys may require slower cutting speeds and more advanced tooling. Moreover, aluminum’s tendency to expand when heated can lead to slight dimensional shifts during the milling process, especially when dealing with high-speed cutting or large components. Understanding these material properties and selecting the appropriate milling parameters is vital for maintaining part accuracy.

4. Programming:

CNC programming determines the paths and operations the machine follows during the milling process. The precision of the final part depends heavily on the accuracy of the CNC code and how well it aligns with the machine's capabilities. Advanced programming techniques, such as 3D toolpath generation and adaptive feeds, can optimize cutting strategies to reduce errors and improve part precision. Conversely, poor programming, such as incorrect tool offsets, incorrect cutting speeds, or inefficient paths, can lead to misaligned cuts, poor surface finishes, and overall imprecision. Therefore, ensuring that CNC programs are meticulously written and optimized is essential for achieving the required tolerances and part accuracy in aluminum milling.

Common Tolerances in Aluminum CNC Milling

1.Standard Tolerances:

In general, standard tolerances for aluminum CNC milling typically range from ±0.005 inches (±0.127 mm) to ±0.020 inches (±0.508 mm), depending on the complexity of the part and the machine's capabilities. For most applications, these tolerances are sufficient to ensure functionality and quality. Parts like brackets, housings, or simple mechanical components often fall within this range.

2.High Precision Tolerances:

For high-precision aluminum CNC milling, tighter tolerances are required. These can range from ±0.001 inches (±0.025 mm) to ±0.0005 inches (±0.0127 mm), depending on the specific part requirements. This level of precision is commonly needed in industries like aerospace, medical devices, and electronics, where even the smallest deviation can impact performance or safety.

3. Examples of Tolerances:

Aerospace Components: Tolerances of ±0.002 inches (±0.051 mm) for structural components like brackets and frames.

Medical Devices: Tolerances as tight as ±0.0005 inches (±0.0127 mm) for parts like surgical instruments.

Electronics: Tolerances of ±0.001 inches (±0.025 mm) for components like connectors and housings to ensure proper fit and function.

Challenges in Achieving High Accuracy

1.Equipment and Technology Limitations:

While modern CNC machines are highly precise, they still have limitations. Older machines or lower-end models may struggle to achieve the tight tolerances required for high-precision aluminum milling. Additionally, machines with less stability or insufficient rigidity can introduce vibrations, reducing accuracy during the cutting process.

2.Challenges Posed by Complex Geometries:

Milling intricate or complex geometries in aluminum can be challenging. The more detailed the design, the harder it becomes to maintain accuracy due to tool deflection, limited tool access, and machining errors. Multi-axis machining helps, but it still requires precise programming and setup to achieve consistent results.

3.Thermal Expansion and Deformation Affecting Precision:

Aluminum’s tendency to expand with heat can cause dimensional shifts during the milling process, especially at high cutting speeds. This thermal expansion can lead to deformation, altering the final dimensions of the part and impacting precision. Managing heat through proper cooling and slower cutting speeds can help mitigate this issue.

How to Improve Accuracy in Aluminum CNC Milling

1.Regular Maintenance:

Routine maintenance is crucial to ensure CNC machines perform at their best. Regular checks on machine parts, such as linear guides, spindles, and motors, help prevent wear and tear that could compromise accuracy. Calibrating the machine regularly ensures that all components are aligned, minimizing errors during the milling process.

2.Optimizing Cutting Parameters:

Optimizing cutting parameters, such as feed rate, cutting speed, and tool path, significantly enhances milling accuracy. By selecting the correct cutting speed for the specific aluminum alloy and adjusting the feed rate for optimal chip removal, the process becomes more stable, resulting in improved part precision and surface finish.

3.Quality Control Measures:

Implementing strict quality control measures throughout the milling process is essential for maintaining high accuracy. This can include regular inspections with tools like coordinate measuring machines (CMM), optical comparators, or laser scanners. By verifying the dimensions and surface quality at various stages, manufacturers can identify and correct issues before they affect the final part.

4.Advanced Technology:

Utilizing advanced technologies, such as 5-axis CNC machines, can greatly improve milling accuracy. These machines offer greater flexibility and control, allowing for more complex geometries and tighter tolerances. The ability to machine from multiple angles in a single setup reduces errors caused by tool changes or misalignments, leading to higher precision in the final product.

FAQ

1.What are the most common applications for aluminum CNC milling?

Aluminum CNC milling is widely used in industries such as aerospace, automotive, electronics, and medical devices. Common applications include manufacturing lightweight structural components, housings, brackets, gears, and intricate parts with tight tolerances. Aluminum’s machinability and strength-to-weight ratio make it ideal for precision-engineered parts.

2.How do material thickness and size affect CNC milling accuracy?

Material thickness and size play a significant role in milling accuracy. Thicker materials may require more power and slower feed rates to ensure consistent cutting. Larger parts may experience deflection during machining, which can lead to dimensional inaccuracies. The proper machine setup, tooling, and cutting parameters help mitigate these issues and maintain precision.

3.What is the difference between CNC milling and traditional milling in terms of accuracy?

CNC milling offers far superior accuracy compared to traditional milling. CNC machines are computer-controlled, allowing for highly precise, repeatable movements with minimal human intervention. In contrast, traditional milling relies on manual adjustments, which can introduce errors due to operator skill and inconsistencies. CNC milling ensures tighter tolerances and higher precision, particularly for complex or high-volume production.

4.Can aluminum CNC milling be used for both prototypes and mass production?

Yes, aluminum CNC milling is suitable for both prototype development and mass production. For prototypes, CNC milling allows for quick and accurate iteration of design concepts with minimal setup changes. In mass production, CNC milling offers high precision, repeatability, and efficiency, making it ideal for producing large quantities of aluminum parts with consistent quality.

Conclusion

In conclusion, the accuracy of aluminum CNC milling is crucial for producing high-quality parts with tight tolerances, especially in industries like aerospace, automotive, and medical devices. The precision of the milling process directly affects the performance, durability, and functionality of the final product. To ensure the best results, it is essential to choose a CNC milling service with advanced equipment, skilled technicians, and a commitment to quality control. Opting for services that utilize high-precision machines, such as 5-axis CNC mills, and employing thorough quality assurance processes will help achieve the required accuracy for both prototypes and mass production. By understanding the factors that influence precision, you can make informed decisions and ensure the success of your aluminum milling projects.