Anodized aluminum is a durable, corrosion-resistant material widely used in industries like aerospace and automotive.

But, even with its impressive benefits, it requires proper cleaning to maintain its appearance and functionality.

In this post, we’ll discuss how to clean anodized aluminum, why regular maintenance is essential, and how to extend its lifespan.

What is Anodized Aluminum and Why Is It Important to Clean?

What is Anodized Aluminum?

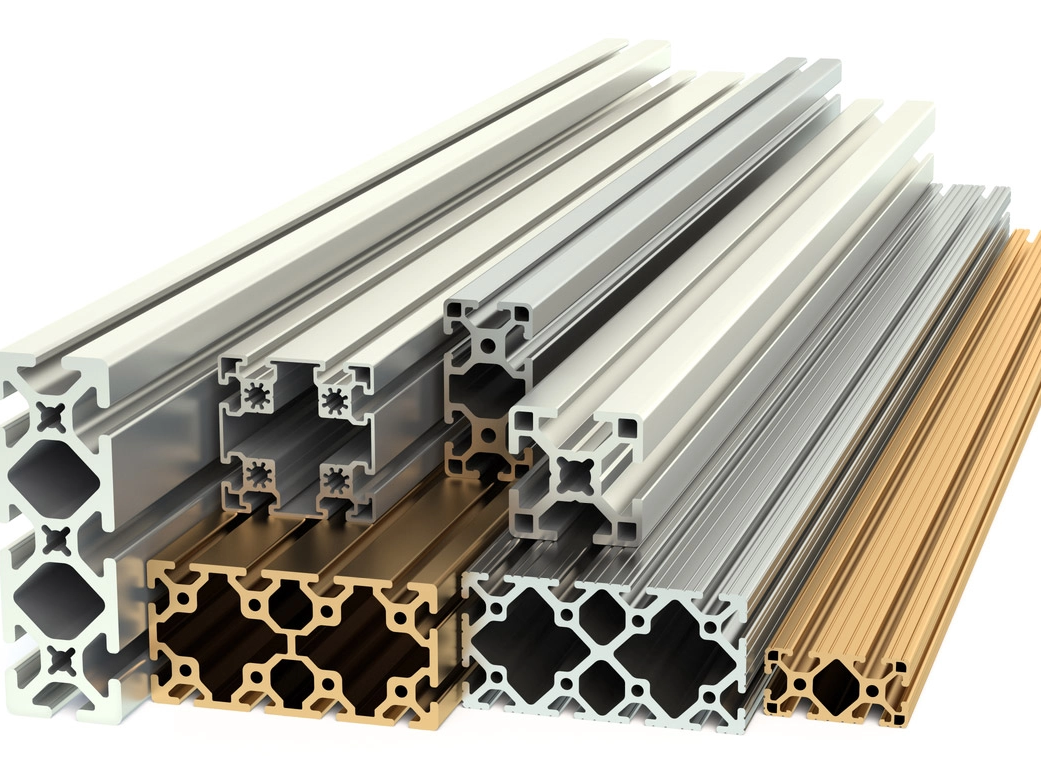

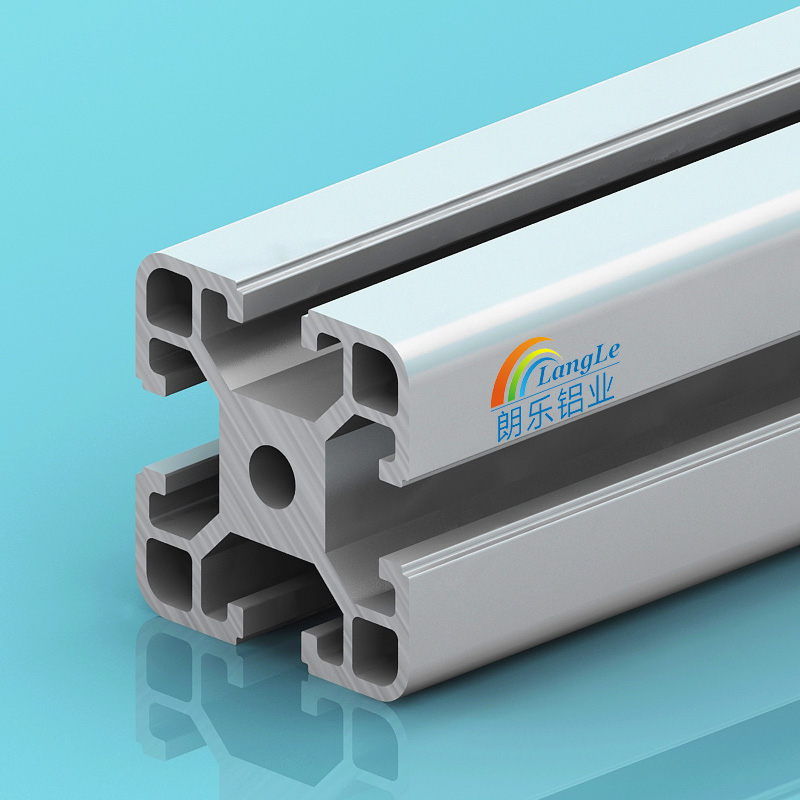

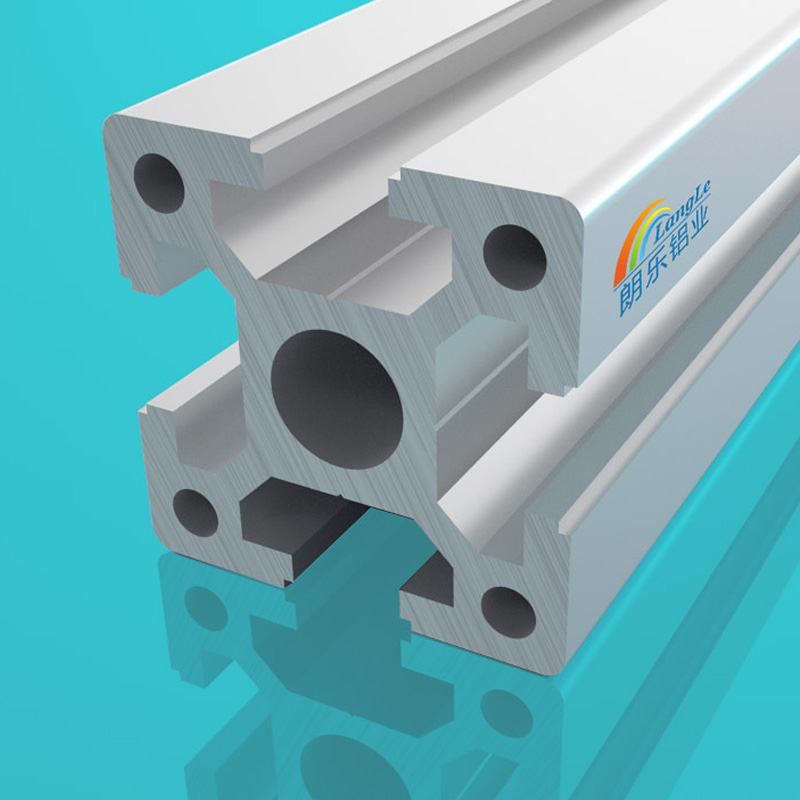

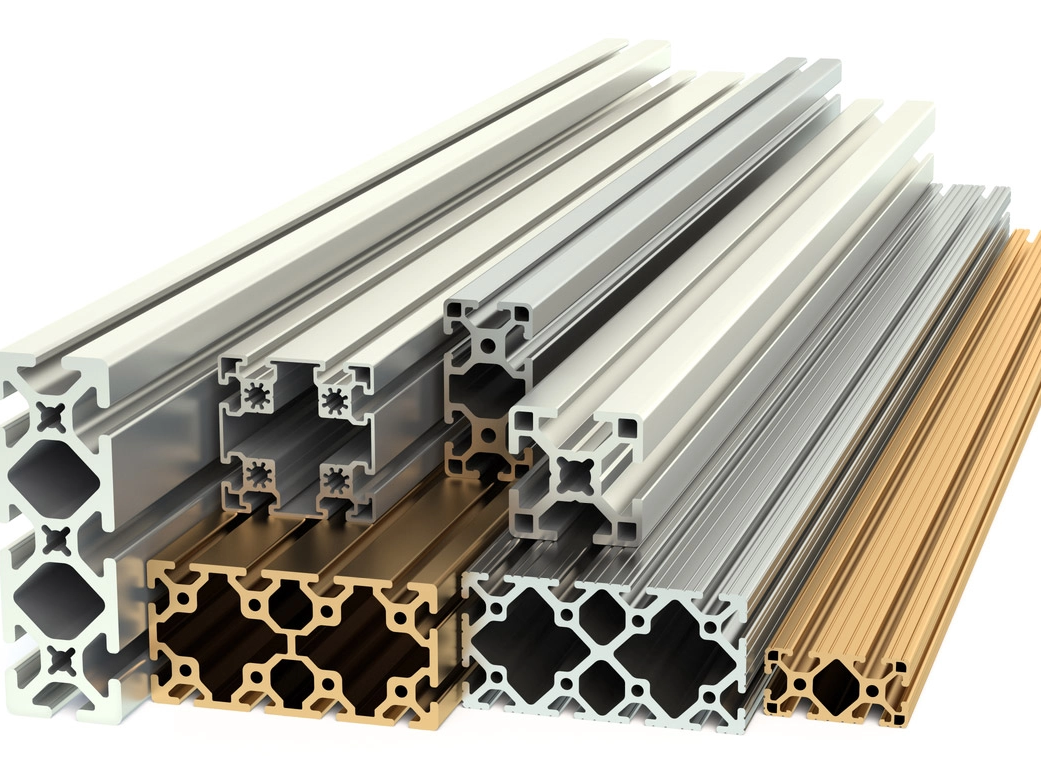

Anodized aluminum is aluminum that has undergone an electrochemical process to form a protective oxide layer. This layer makes it highly resistant to corrosion and wear, which is why anodized aluminum is popular in various industries.

Some of the key benefits include:

Durability: It withstands harsh environmental conditions.

Corrosion Resistance: It protects against rust and deterioration.

Anodized aluminum is widely used in industries such as:

Aerospace: For aircraft components.

Automotive: In car parts exposed to the elements.

Architecture: For window frames, building facades, and structural elements.

Consumer Goods: In products like kitchen appliances and mobile devices.

Why Cleaning Anodized Aluminum is Important

While anodized aluminum is durable, it still requires regular cleaning to maintain its quality and longevity. Without proper care, the surface can become scratched, discolored, or even corroded over time.

Here’s why cleaning is essential:

Prevents Wear and Corrosion: Dirt, dust, and pollutants can cause the surface to deteriorate, reducing its protective qualities.

Extends Lifespan: Regular cleaning removes contaminants that can damage the finish, ensuring that anodized aluminum lasts longer.

Preserves Appearance: Cleaning helps maintain the shiny, smooth finish of anodized aluminum, preserving its aesthetic appeal.

Avoids Irreversible Damage: Neglecting to clean anodized aluminum regularly can lead to permanent stains or corrosion that are difficult to fix.

How to Clean Anodized Aluminum: Step-by-Step Instructions

Essential Tips for Cleaning Anodized Aluminum

Use of Neutral Cleaners

To clean anodized aluminum effectively, always opt for neutral cleaners. These cleaners have a pH range of 6-8 and are non-reactive with the anodized layer, ensuring the surface stays intact.

Why Neutral Cleaners Are Ideal: They prevent damage to the protective layer, unlike harsh chemicals.

Avoid Harsh Chemicals: Acidic or alkaline cleaners can break down the anodized finish, leading to permanent damage.

Recommended Products: Mild dish soap or gentle, pH-balanced cleaners work best.

Avoid Abrasive Materials

Abrasive materials like steel wool, sandpaper, or emery paper can scratch and dull anodized aluminum. These scratches compromise the protective coating.

Why Abrasives Are Harmful: They wear down the anodized layer, allowing moisture and contaminants to cause damage.

Recommended Tools: Always use soft cloths, sponges, or microfiber towels to clean anodized aluminum without harming the surface.

Always Test First

Before cleaning the entire surface, test your cleaning method on a small, inconspicuous area. This ensures the cleaner or tool won’t cause any unwanted damage.

Why Testing Is Important: It helps identify potential risks like color fading or scratching before they spread across the entire surface.

How to Test: Choose a hidden area to check for discoloration or surface damage after cleaning.

Step-by-Step Cleaning Process

Step 1: Remove Loose Dirt and Dust

Start by using a damp sponge or cloth to gently wipe away surface dirt and dust.

Best Cleaning Techniques: For light soil, a simple damp cloth is often enough to remove particles without scrubbing.

Step 2: Apply a Cleaning Solution

Mix mild dish soap or a neutral cleaner with water. Apply the solution using a soft cloth or sponge.

How to Prepare: Use about a tablespoon of soap per gallon of water. Ensure the solution is not too concentrated.

Step 3: Scrub Stubborn Dirt (if necessary)

If dirt remains, use a gentle scrubber to tackle tougher grime. Always scrub along the metal grain to avoid scratches.

Proper Technique: Scrub gently with even pressure to avoid damaging the finish.

Step 4: Rinse Thoroughly

Rinse the surface with clean water to remove any cleaner and debris left behind.

Ensure Complete Rinsing: Make sure all cleaning solution residue is washed away to prevent streaking or staining.

Step 5: Dry the Surface

Use a soft towel or microfiber cloth to dry the surface. This prevents water spots and streaks.

Why Drying Immediately Is Important: It prevents mineral deposits and keeps the aluminum looking clean and fresh.

How to Maintain Anodized Aluminum for Long-Term Care

Regular Cleaning Schedule

For long-term care, clean anodized aluminum at least once a year. In areas with high pollution, you may need to clean it more frequently.

Cleaning Frequency: Coastal areas with salt exposure or industrial zones may require more frequent cleaning.

Why Regular Maintenance Matters

Regular cleaning prevents dirt buildup and keeps the anodized aluminum protected. It also ensures the surface remains visually appealing.

How to Handle Weather-Related Damage

In environments where salt and pollution are prevalent, like coastal or urban areas, cleaning regularly will help prevent surface wear.

Dealing with Environmental Effects: Smog, condensation, and saltwater exposure can accelerate damage, so more frequent cleaning is necessary.

Troubleshooting Common Issues with Anodized Aluminum

How to Handle Oxidation and Discoloration

What Causes Oxidation on Anodized Aluminum?

Oxidation occurs when anodized aluminum is exposed to moisture, salts, and air over time. The protective anodized layer can break down, leading to discoloration and rust. This is more common in coastal or industrial areas with high humidity or salty air.

Exposure to Elements: Saltwater, moisture, and pollution can lead to oxidation.

How to Clean Oxidation

To clean oxidation, use mild abrasives or oxidation-specific cleaners. These products help remove the oxidized layer without damaging the underlying aluminum.

Cleaning Techniques: Use a nylon brush or soft abrasive pad and scrub gently along the grain to prevent further damage.

Oxidation-Specific Cleaners: Products designed for anodized surfaces can effectively restore the appearance.

Preventing Future Oxidation

After cleaning oxidation, it's important to apply a protective coating. This coating helps seal the anodized layer, preventing further exposure to harmful elements.

Protective Coatings: Clear sealants or waxes can help prevent oxidation from recurring.

Regular Maintenance: Cleaning anodized aluminum regularly reduces the chances of oxidation buildup.

Dealing with Scratches and Wear on Anodized Aluminum

How Scratches Affect Anodized Aluminum

Scratches on anodized aluminum can be especially problematic. They break through the anodized layer, exposing the raw aluminum underneath, which is more susceptible to damage.

Why Scratches Are Problematic: They compromise the protective layer, leading to potential corrosion and discoloration.

How to Fix Minor Scratches

For minor scratches, touch-up paint or clear coatings can be applied. This helps restore the protective layer and prevents further damage.

Touch-Up Paint: Match the paint to the original color of the anodized surface for seamless repair.

Clear Coatings: Apply a thin layer to protect the scratched area.

When to Seek Professional Help

If scratches are deep or extensive, it’s best to seek professional refinishing services. Professionals can restore the surface, remove oxidation, and even re-anodize the aluminum for a fresh, durable finish.

Professional Services: They can fix deeper scratches, discoloration, or extensive damage to the anodized layer.

Professional Care for Anodized Aluminum

When to Call in the Experts

Handling Severe Damage

If anodized aluminum shows signs of deep oxidation, fading, or corrosion, professional refinishing might be necessary. These issues often go beyond what can be fixed with regular cleaning and touch-ups.

Oxidation: When oxidation becomes severe, it can weaken the protective layer.

Fading: Sun exposure or weathering can cause anodized surfaces to lose their color and sheen.

Corrosion: Prolonged exposure to harsh elements can cause irreversible damage to the finish.

Refinishing and Restoration Services

Professional refinishing services specialize in restoring anodized aluminum. These services can address extensive damage, including fading and deep oxidation, and reapply the anodized coating for long-lasting protection.

Restoring Color and Finish: Professionals can bring back the original appearance of anodized aluminum by removing oxidation and applying a fresh anodizing layer.

Re-anodizing: This process involves reapplying a new anodized layer, which helps the aluminum regain its strength and corrosion resistance.

The Benefits of Professional Refinishing

Rejuvenating Faded Finishes

When anodized aluminum begins to fade, professionals can restore its vibrant color. This process involves cleaning, polishing, and applying protective coatings to rejuvenate the surface.

Restoring Luster: Experts use advanced techniques to bring back the original sheen and color to faded surfaces.

Protecting Aluminum for the Future

After refinishing, it's important to apply high-quality sealants. These products protect the newly restored surface from future damage, including oxidation, scratches, and discoloration.

Applying Sealants: Experts apply durable coatings to ensure long-term protection.

Extending Lifespan: Regular refinishing and sealing help maintain anodized aluminum's appearance and durability for years.

Best Practices for Preventing Damage to Anodized Aluminum

Protective Measures for Anodized Aluminum Surfaces

Protective Coatings

Applying clear coatings or sealants can significantly extend the life of anodized aluminum. These coatings form a protective layer over the anodized finish, helping to prevent damage from environmental factors like dirt, moisture, and chemicals.

How Coatings Work: Clear sealants protect the anodized surface, making it more resistant to scratches, stains, and oxidation.

Environmentally Safe Cleaning Products

When cleaning anodized aluminum, it's crucial to choose environmentally friendly products. Harsh chemicals can damage the anodized layer and harm the environment.

Choosing the Right Products: Opt for non-toxic, biodegradable cleaners that are gentle on both anodized surfaces and the planet.

Avoiding Harsh Weather Conditions

How Extreme Temperatures or Prolonged Exposure to Rain and Sun Affect Anodized Aluminum

Exposing anodized aluminum to extreme temperatures or long periods of direct sunlight can cause the surface to degrade over time. Prolonged exposure to rain, especially in coastal areas with salt, can speed up oxidation.

Impact of Temperature and Weather: High heat can cause the anodized layer to lose its integrity, while UV rays from the sun can cause fading. Rainwater can leave mineral deposits or accelerate corrosion if not cleaned regularly.

Conclusion

Regular cleaning and proper maintenance are key to preserving anodized aluminum. Careful attention helps extend its lifespan and maintain its appearance. By investing in the right tools and cleaning products, you can ensure your anodized surfaces stay protected and beautiful for years to come.