Introduction

The cost of Aluminum Extrusion per pound is a critical factor for industries relying on aluminum components. Understanding the pricing dynamics is essential for budgeting and cost management in manufacturing processes. This article delves into the various elements that influence aluminum extrusion prices, offering a comprehensive analysis to help businesses make informed decisions.

Factors Influencing the Price of Aluminum Extrusion

Raw Material Costs

The primary determinant of aluminum extrusion pricing is the cost of raw aluminum. Aluminum prices are subject to fluctuations based on global commodity markets. Factors such as mining output, geopolitical stability, and international trade policies can cause significant variability in raw material costs. For instance, supply disruptions in major aluminum-producing countries can lead to price spikes.

Energy Prices

Aluminum production is energy-intensive, requiring substantial electricity for smelting and extrusion processes. Energy prices, therefore, have a direct impact on production costs. Regions with lower energy costs can produce aluminum extrusions more economically. Conversely, increases in oil, gas, or electricity prices can lead to higher costs per pound of aluminum extrusion.

Manufacturing Processes

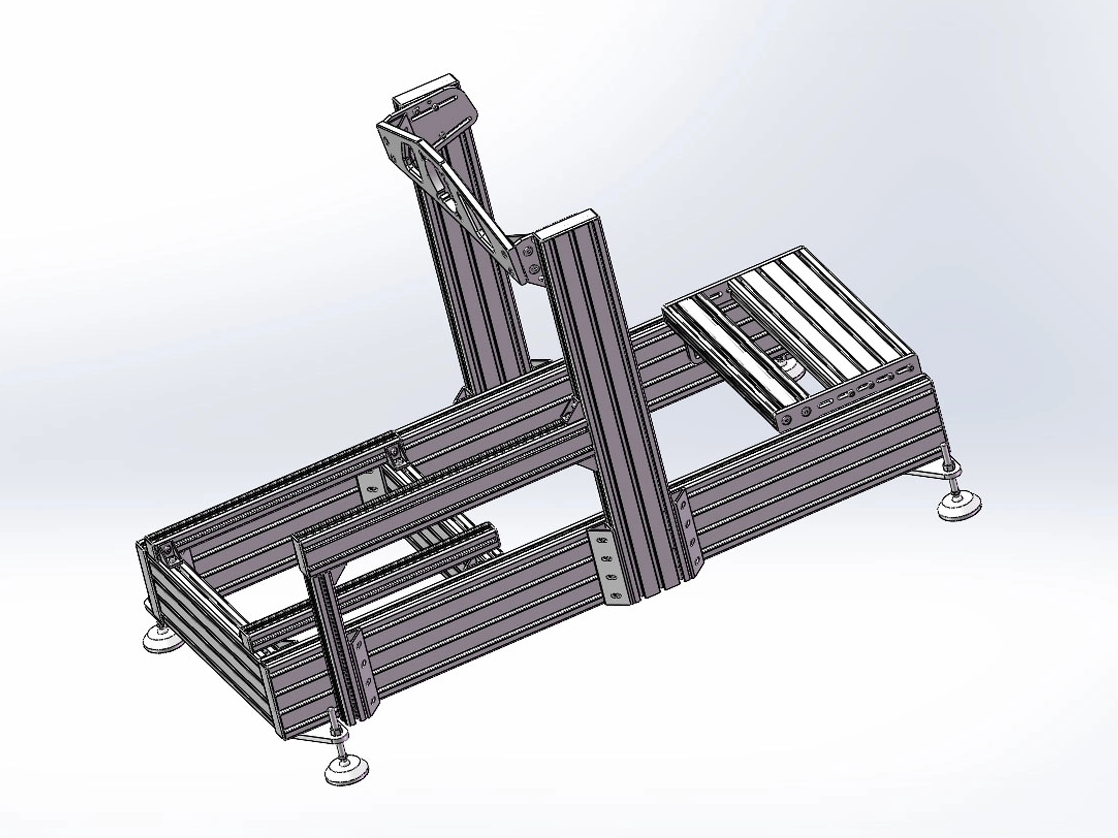

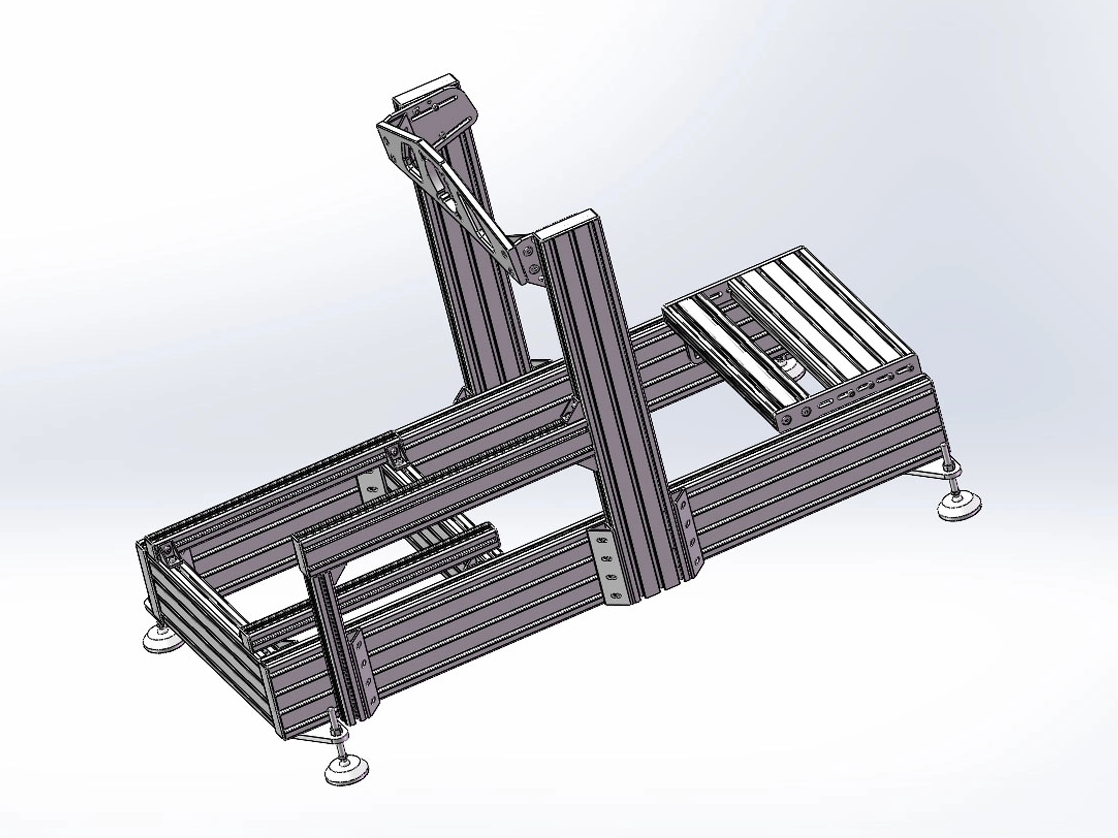

The complexity of the extrusion process affects the overall cost. Custom extrusions with intricate designs require more specialized equipment and skilled labor, increasing the price. Additionally, factors such as die design, extrusion speed, and quality control measures contribute to the cost. Advanced technologies, like precision CNC machining, can enhance product quality but may also raise the price per pound.

Market Demand and Supply

Market dynamics play a significant role in aluminum extrusion pricing. High demand from industries such as automotive, construction, and aerospace can drive up prices. Supply chain disruptions, whether from natural disasters or logistical challenges, can also affect availability and cost. Monitoring market trends is essential for anticipating price changes.

Understanding Aluminum Extrusion Pricing Structures

Cost Per Pound vs. Cost Per Piece

Pricing aluminum extrusions can be based on weight (per pound) or per unit. Cost per pound is common for bulk orders where the weight of the material is the primary concern. However, for custom parts with specific dimensions and tolerances, pricing per piece may be more appropriate. It's important to clarify with suppliers how they structure their pricing to accurately estimate costs.

Custom vs. Standard Extrusions

Standard extrusions, produced in common shapes and sizes, are generally less expensive due to economies of scale. Custom extrusions, tailored to unique specifications, involve additional costs for die creation and setup. The level of customization, including cross-sectional design and required tolerances, will influence the final price per pound.

The Impact of Alloy Types on Pricing

Common Aluminum Alloys

Aluminum extrusions are available in various alloys, each with distinct properties and cost implications. The 6000 series, particularly 6061 and 6063 alloys, are widely used due to their excellent extrudability and balance of strength and corrosion resistance. These common alloys are typically more affordable and readily available.

Specialty Alloys

Specialty alloys, such as those in the 7000 series, offer higher strength and are used in demanding applications like aerospace. However, these alloys are more expensive due to higher raw material costs and more complex processing requirements. Selecting the appropriate alloy is crucial for meeting performance requirements without incurring unnecessary expenses.

Additional Services Affecting Cost

Anodizing and Finishing

Surface treatments such as anodizing, painting, or powder coating enhance corrosion resistance and aesthetic appeal. These finishing processes add to the overall cost per pound. The type of finish, thickness of the coating, and color requirements can all influence pricing. Anodized Aluminum Extrusion is popular for its durability and appearance.

Machining and Fabrication

Post-extrusion processes like CNC machining, drilling, tapping, and cutting are often required to prepare extrusions for assembly or installation. These additional fabrication steps increase labor costs and machine time, thereby increasing the price per pound. Working with suppliers that offer integrated services can optimize costs and streamline production.

How to Get Accurate Pricing for Aluminum Extrusion

Working with Suppliers

Establishing a relationship with reputable suppliers is crucial. A reliable supplier will provide transparent pricing and help identify cost-saving opportunities without compromising quality. Companies like YURUN Aluminum Co., LTD offer extensive expertise in producing high-quality Aluminum Extrusion products.

Requesting Quotes

To obtain accurate pricing, provide detailed specifications when requesting quotes. Include information on alloy type, dimensions, tolerances, surface finish requirements, and any additional processing. Detailed drawings or models can facilitate precise quotations. Comparing quotes from multiple suppliers can help identify the best value.

Conclusion

Understanding the factors that influence the price of aluminum extrusion per pound empowers businesses to make strategic decisions regarding material selection and supplier partnerships. By considering raw material costs, energy prices, manufacturing complexities, and additional services, companies can optimize their use of Aluminum Extrusion in production while controlling expenses. Engaging with experienced suppliers and clearly communicating requirements are essential steps toward achieving cost-effective solutions.

"}