Confusing a cast aluminum component with an extruded profile is more than a simple clerical error; it represents a significant engineering risk. In high-stress applications, swapping these materials can lead to catastrophic structural failure, anodizing defects that ruin aesthetics, or unexpected brittleness during machining. While both processes start with aluminum alloys, the thermal histories and mechanical pressures they undergo create fundamentally different grain structures. These differences dictate how the metal handles load, how it accepts surface finishing, and how it reacts to welding.

For procurement officers, quality engineers, and supply chain managers, the ability to verify a part's origin without sending it to a lab is a vital skill. You do not always need destructive testing to validate a supplier's claim. By observing surface textures, geometric consistency, and machining behaviors, you can often determine the manufacturing method right on the receiving dock. This guide provides a systematic framework on how to tell if aluminum is cast or extruded?, ensuring you make informed decisions for your assembly's safety and longevity.

Key Takeaways

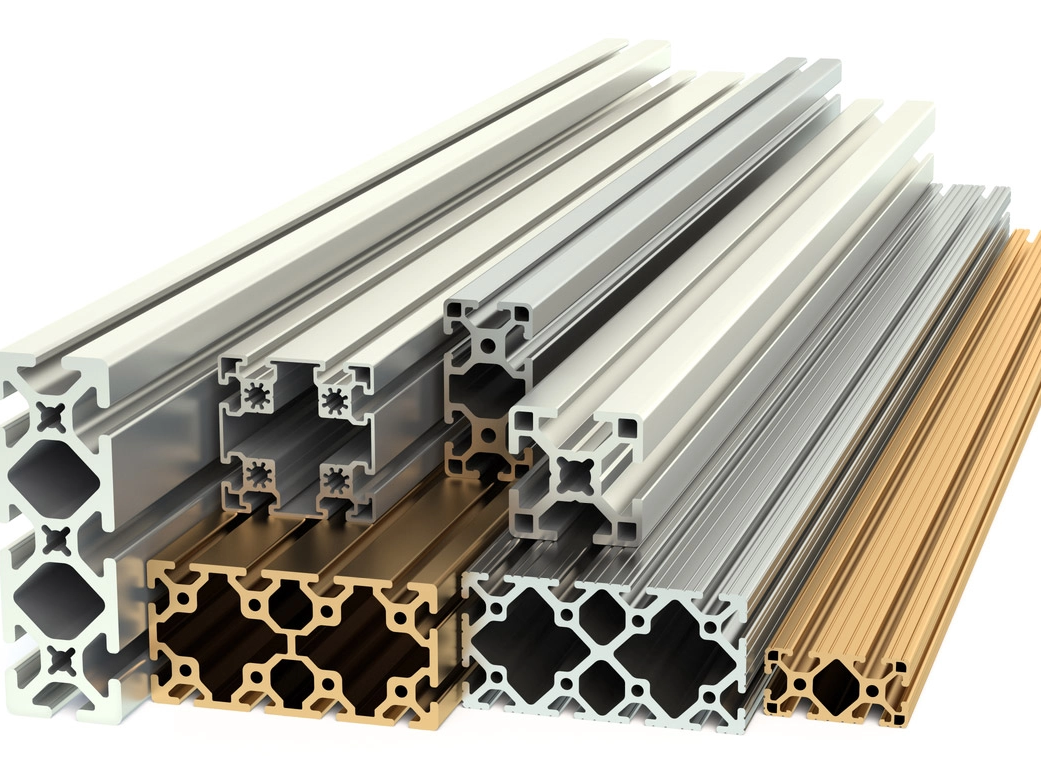

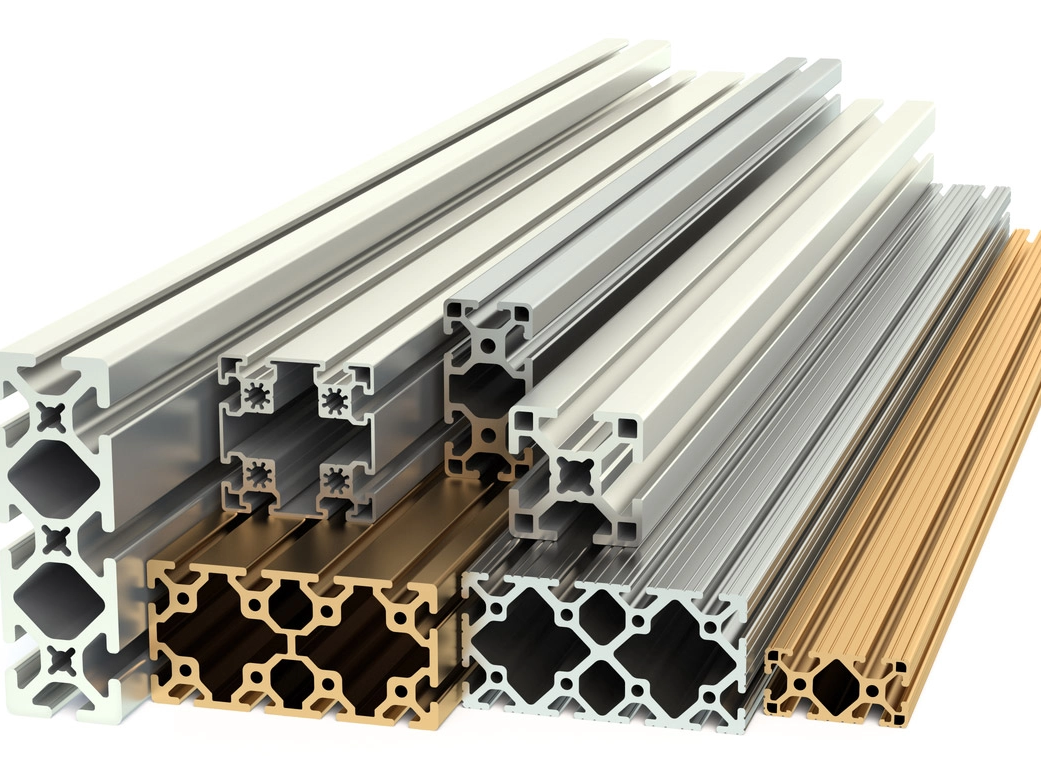

Visual Cues: Castings often exhibit a rougher, pebbled surface with potential porosity, whereas extrusions show linear die lines and a smoother finish.

Cross-Section Logic: Extrusions must have a consistent cross-section (2D profile), while castings can achieve complex, solid 3D geometries with varying wall thicknesses.

Finishing Response: Extruded aluminum generally accepts anodizing with a uniform finish; cast aluminum frequently appears blotchy or dull due to silicon content and grain structure.

Cost Implications: Casting suits high-volume, complex 3D shapes; extrusion offers lower tooling costs for consistent profiles and structural framing.

Understanding the Process: Cast Aluminum vs. Aluminum Extrusion

To identify the physical evidence on a part, you must first understand the violence or flow that created it. The manufacturing process imprints a DNA onto the metal that remains visible long after production finishes. Understanding these mechanisms establishes the baseline for all visual and physical inspections.

The Casting Mechanism

Casting involves heating aluminum until it becomes a molten liquid. Manufacturers pour or inject this liquid into a mold cavity (die casting, sand casting, or investment casting). As the liquid cools, it solidifies into the shape of the mold.

The defining characteristic here is an isotropic grain structure. Because the metal cools from a liquid state without directional pressure, the grains grow relatively evenly in all directions. This allows for incredible geometric freedom, enabling complex 3D shapes with varying wall thicknesses. However, this process introduces the risk of porosity—tiny air pockets trapped inside the metal as it solidifies.

The Extrusion Mechanism

In contrast, Aluminum Extrusion does not involve melting the metal into a liquid soup. Instead, a solid cylindrical billet is heated until it reaches a plastic state—soft enough to deform but still solid. A hydraulic ram forces this softened aluminum through a steel die, much like squeezing toothpaste from a tube.

The key characteristic of this process is a directional grain structure. The immense pressure elongates the aluminum grains in the direction of flow. This results in superior strength along the longitudinal axis and a strictly uniform cross-section. The profile emerging from the die is identical at the front and the back, which is a primary constraint of the process.

Why It Matters for Buyers

The process dictates the allowable tolerances and surface quality. If you require tight tolerances on a long, straight rail, extrusion is the natural choice. If you need a complex housing with internal ribs and bosses that vary in height, casting is necessary. Recognizing these limitations helps you spot when a supplier might be substituting a cheaper casting for a specified extrusion, or vice versa.

Visual Identification: Surface Texture, Defects, and Geometry

The most immediate method to verify the material is a visual inspection. You can usually perform this field test with the naked eye or a simple magnifying glass. The surface finish and geometric constraints serve as the primary indicators.

Surface Finish Inspection

The skin of the aluminum tells the story of its creation. Cast aluminum typically displays a rougher texture. Unless it has been fully machined, you will often see a pebbled or orange peel surface. This texture results from the molten metal solidifying against the mold walls. Furthermore, castings almost always have a parting line. This is a visible seam where the two halves of the mold met. Manufacturers may grind this down, but a faint line often remains.

Conversely, aluminum extrusion generally presents a much smoother finish. The tell-tale sign here is the presence of die lines. These are faint, parallel longitudinal striations that run the entire length of the part. They are caused by microscopic imperfections in the die as the metal slides through it. If you see lines running parallel to the long axis of the part, it is likely extruded.

Geometric Constraints

Geometry is perhaps the most reliable logic test. Extrusion creates a 2D profile extruded into a 3D length. Therefore, the cross-section must be consistent.

The Through-Hole Test: Look at the internal features. If the part has a hole, channel, or void, does it run the entire length of the part? If you see a blind pocket (a hole that stops halfway) or internal ribs that change direction, the part is likely cast. Extrusion dies cannot create blocked-off pockets; the mandrel must extend through the entire die stack.

Uniformity: If you slice the part at any point along its length and the profile remains identical, it is a strong candidate for aluminum extrusion. Casting allows for tapered walls, bosses, and features that exist only in specific locations.

Common Defect Markers

Defects are undesirable, but they are excellent identifiers. Different processes produce different types of flaws.

| Feature | Cast Aluminum Defects | Extruded Aluminum Defects |

|---|

| Porosity | Pinholes, blowholes, or shrinkage voids (spongy appearance). | Rare internal porosity; occasional piping at the end of the billet. |

| Surface Marks | Flow marks or cold shuts (where two molten flows met but didn't fuse). | Drag marks, die lines, or surface tearing (speed cracks). |

| Shape | Flash (excess metal at the parting line). | Twist or bow (deformation along the length). |

Physical & Chemical Indicators: Anodizing and Machining

Sometimes visual cues are obscured by paint or heavy polishing. In these cases, secondary verification methods involving chemical response and physical behavior become useful. These are particularly helpful during the prototyping or evaluation phase.

The Anodizing Test

Anodizing involves an electrochemical process that thickens the natural oxide layer on the aluminum. The alloy composition significantly affects the outcome. Extruded aluminum typically utilizes the 6000 series alloys (like 6061 or 6063). These alloys contain magnesium and silicon but generally possess a microstructure that accepts anodizing well. The result is a clear, uniform, and vibrant finish. If the part looks metallic and satin-smooth after anodizing, it is likely extruded.

Cast aluminum alloys, such as A356 or A380, often contain high levels of silicon (sometimes 7% to 12%) to improve the flow of the molten metal. Silicon does not dissolve well during the anodizing process. Consequently, anodized castings often turn a dull dark gray, black, or blotchy color. The surface may look smutty. If you try to anodize a part and it comes out looking dirty or significantly darker than expected, you are likely dealing with cast aluminum.

Machining Behavior

If you have the opportunity to machine the part, the chips produced provide immediate feedback.

Chip Formation: Extruded aluminum (especially 6061) is ductile. When you drill or mill it, it produces long, continuous, curly chips. Machinists often describe it as gummy.

Brittleness: Cast aluminum is more brittle due to the grain structure and silicon content. When machined, it tends to chip break easily. You will often see short, discontinuous chips or even powder rather than long spirals. If the material feels crunchy or turns to dust under the tool, it is almost certainly cast.

Weight and Density Nuances

Theoretically, the density of aluminum alloys is roughly similar. However, the manufacturing process introduces variables. Casting porosity—even microscopic—can slightly reduce the effective density of a component. Extrusion creates a fully dense, compressed structure. While this difference is often too small to detect by hand, precise weight measurement compared to the CAD model volume can sometimes reveal the lower density of a porous casting.

Evaluating Functional Trade-offs: Strength and Application

Identifying the process is not just about labeling; it is about determining suitability for the application. Engineers and procurement teams must decide which method provides the necessary structural integrity.

Structural Integrity

Extrusions generally offer higher tensile strength and ductility, particularly in the direction of the extrusion. The elongated grain structure aligns with the stress paths in linear framing, rails, and beams. If the application involves high tensile loads or needs to flex without snapping, Aluminum Extrusion is the superior choice.

Castings are better suited for stiffness in complex geometries. For components like engine blocks, gearboxes, or brackets that require rigidity in multiple directions, casting is ideal. However, castings usually have lower tensile strength and elongation compared to their wrought counterparts. They are more prone to sudden fracture under shock loads due to their brittle nature.

Heat Treatment Response

Heat treating affects these materials differently. You might see a T6 temper designation on both cast (e.g., A356-T6) and extruded (e.g., 6061-T6) parts. While both undergo solution heat treatment and artificial aging, the starting microstructure limits the casting. A casting will almost always have lower fatigue strength than an extrusion of comparable hardness, simply because of potential internal defects and grain structure.

Weldability Factors

Welding poses a significant challenge for castings. The internal porosity acts as a trap for gases. When you melt the weld pool, these gases expand and bubble out, creating a porous, weak weld. While high-quality castings can be welded, it requires skill and specific alloys. Extruded alloys, particularly the 6000 series, are famous for their excellent weldability. If the part is part of a welded assembly, extrusion is typically the safer specification.

TCO and Manufacturing Scalability

Finally, the business case often dictates the choice between these two methods. Understanding the Total Cost of Ownership (TCO) helps explain why a supplier might have chosen one path over the other.

Tooling Investment

Extrusion dies are relatively inexpensive. A standard profile die might cost a few thousand dollars, and complex ones rarely exceed moderate figures. This allows for a rapid Return on Investment (ROI), making extrusion viable even for mid-volume runs of linear shapes.

Casting molds, especially for high-pressure die casting, are capital-intensive. Hardened steel molds can cost tens or hundreds of thousands of dollars. This high barrier to entry means casting is only economically viable when amortized over high production volumes (typically tens of thousands of units).

Machining Requirements

Extrusion provides a near-net shape for linear profiles. However, if the final part needs holes, slots, or notches, these must be machined in a secondary step. This adds cost.

Casting shines here by molding features in place. A complex housing can come out of the mold with holes, bosses, and logos already formed. This can significantly reduce the total machining time required. For complex 3D geometries, casting often offers a lower TCO despite the higher initial tooling cost.

Lead Time Considerations

If speed is the priority, extrusion usually wins on prototyping. Cutting a new die and extruding a sample can happen in weeks. Designing, machining, and testing a casting mold is a months-long process. If you need rapid iteration on a frame design, stick to extrusion.

Conclusion

Correctly identifying whether an aluminum part is cast or extruded relies on a triangulation of evidence. You rarely rely on a single factor. Instead, you combine visual data (die lines vs. pebbled texture), geometric logic (uniform profile vs. 3D complexity), and chemical response (anodizing color) to form a conclusion.

This verification is a prerequisite for quality control. Using a brittle cast part where a ductile extrusion was specified can compromise the safety of a structure. Conversely, forcing an extrusion into a complex shape that should have been cast can lead to excessive machining costs and waste. We encourage you to use this guide for initial inspection, but always validate your findings by requesting Material Test Reports (MTRs) from your suppliers. This documentation provides the ultimate proof of origin, ensuring your project meets all engineering standards.

FAQ

Q: Is cast aluminum stronger than aluminum extrusion?

A: Generally, no. Extruded aluminum typically possesses higher tensile strength and ductility due to its directional grain structure and lack of porosity. While some high-performance cast alloys exist, extrusions are superior for structural, load-bearing applications. Castings are better used for rigid, complex shapes where tensile loads are lower.

Q: Can you anodize cast aluminum?

A: You can, but the results are often poor visually. Cast aluminum usually contains high silicon levels to help the metal flow into the mold. Silicon turns dark gray or black during anodizing, leading to a dull, smutty, or blotchy finish. Extruded aluminum produces a much cleaner, clearer anodized color.

Q: Which is cheaper: casting or extrusion?

A: It depends on volume and shape. Extrusion has much lower tooling costs, making it cheaper for low-to-mid volumes of linear profiles. Casting has very high tooling costs but very low per-part costs for high volumes. For complex 3D shapes produced in the thousands, casting is usually the more improved economic choice.

Q: How can I tell the difference if the part is painted?

A: Paint hides the surface texture, so rely on geometry. Look for a parting line (a seam from the mold), which indicates casting. Check for blind holes or variable wall thicknesses, which are impossible in extrusion. If the cross-section is perfectly uniform from end to end, it is likely extruded.