CNC machining is a cutting-edge manufacturing process used to create highly precise parts. But is it truly a key part of modern manufacturing? In this article, we’ll explore how CNC machining fits into the larger manufacturing landscape. You’ll learn about its role, benefits, and applications in various industries.

What is CNC Machining?

CNC machining is a manufacturing process controlled by computers. It uses digital instructions to guide machines in shaping and cutting materials precisely. This process is essential for making complex parts that need to meet strict tolerances.

How Does CNC Machining Work?

CNC machines are guided by G-code, a set of digital instructions. These instructions come from CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, which convert designs into machine movements. CNC machines can perform various tasks, such as drilling, milling, and turning, all with minimal human intervention.

Why is CNC Machining Important?

CNC machines are crucial for producing parts with high precision. They can create complex shapes, from simple brackets to intricate aerospace components. The automation ensures repeatability and accuracy, making them perfect for large-scale production. Without CNC machining, many industries would struggle to meet their high-quality standards.

The Role of CNC Machining in Manufacturing

CNC machining plays a pivotal role in modern manufacturing. It fits into the broader landscape by automating complex processes that were once performed manually. This makes it essential for industries that require high precision and mass production.

Traditional Manufacturing vs. CNC Machining

In traditional methods, machines rely heavily on manual labor. Workers control the speed, movement, and tool changes. This limits precision and repeatability. CNC machining, on the other hand, uses computer control, which reduces human error and ensures consistent results across all parts.

Efficiency and Precision Benefits

CNC machining is faster than traditional methods, especially for large runs. It allows for rapid production, reducing lead times. The precision it offers ensures parts are produced with tight tolerances, making it ideal for industries like aerospace and medical manufacturing, where accuracy is critical.

How Does CNC Machining Work in the Manufacturing Process?

CNC machining is a precise and automated process that transforms raw materials into finished parts. It all starts with a design created in CAD (Computer-Aided Design) software. The design is then converted into G-code, which tells the CNC machine how to move and shape the material.

The Steps in CNC Machining

1. Design: Engineers create the part using CAD software.

2. Programming: The design is converted into G-code through CAM (Computer-Aided Manufacturing) software.

3. Machine Setup: The material is loaded, and the machine is set up with the necessary tools.

4. Machining: The CNC machine follows the G-code to cut, shape, and finish the part.

5. Finishing: After the main machining process, parts may go through additional steps like polishing or coating.

Key Components in CNC Machining

CAD Software: Creates the digital design of the part.

G-code: The language that guides the CNC machine.

Machine Tools: Equipment like drills, mills, and lathes that perform the actual cutting and shaping.

Importance of Automation

The automated nature of CNC machining ensures precision. Machines repeat the same movements exactly, resulting in consistent parts. This eliminates human error, allowing manufacturers to produce high-quality products at scale.

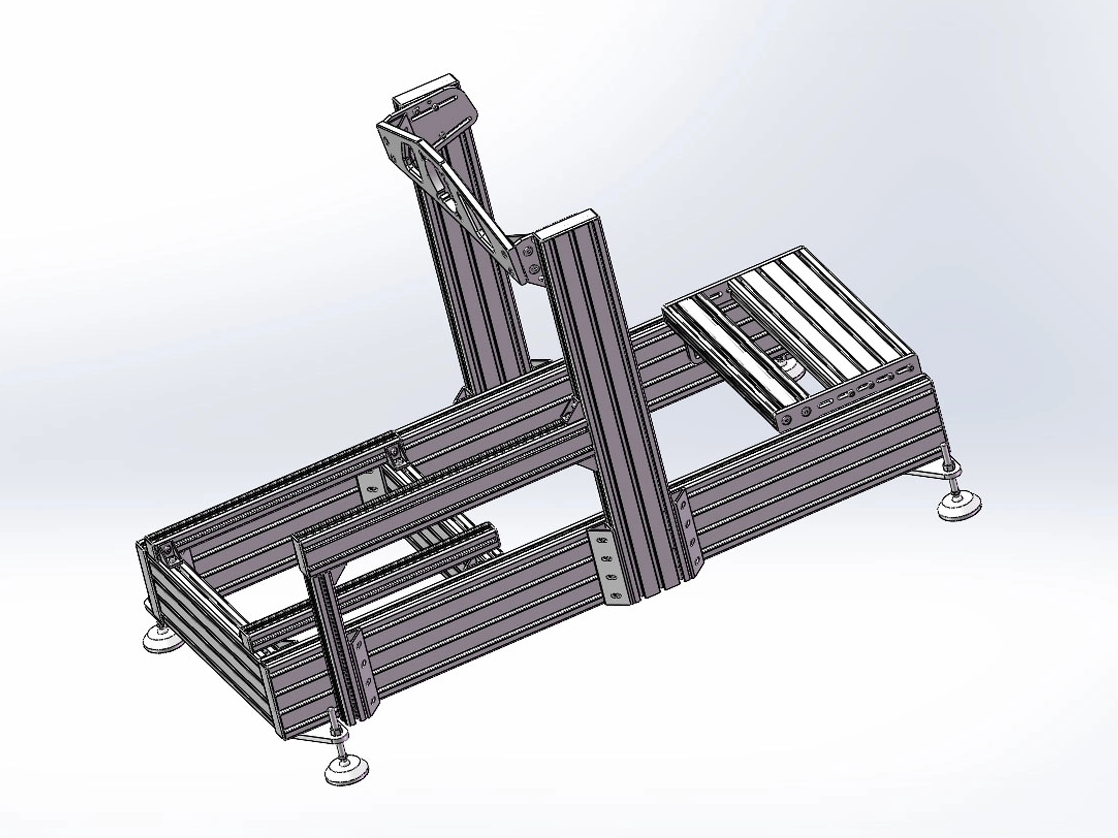

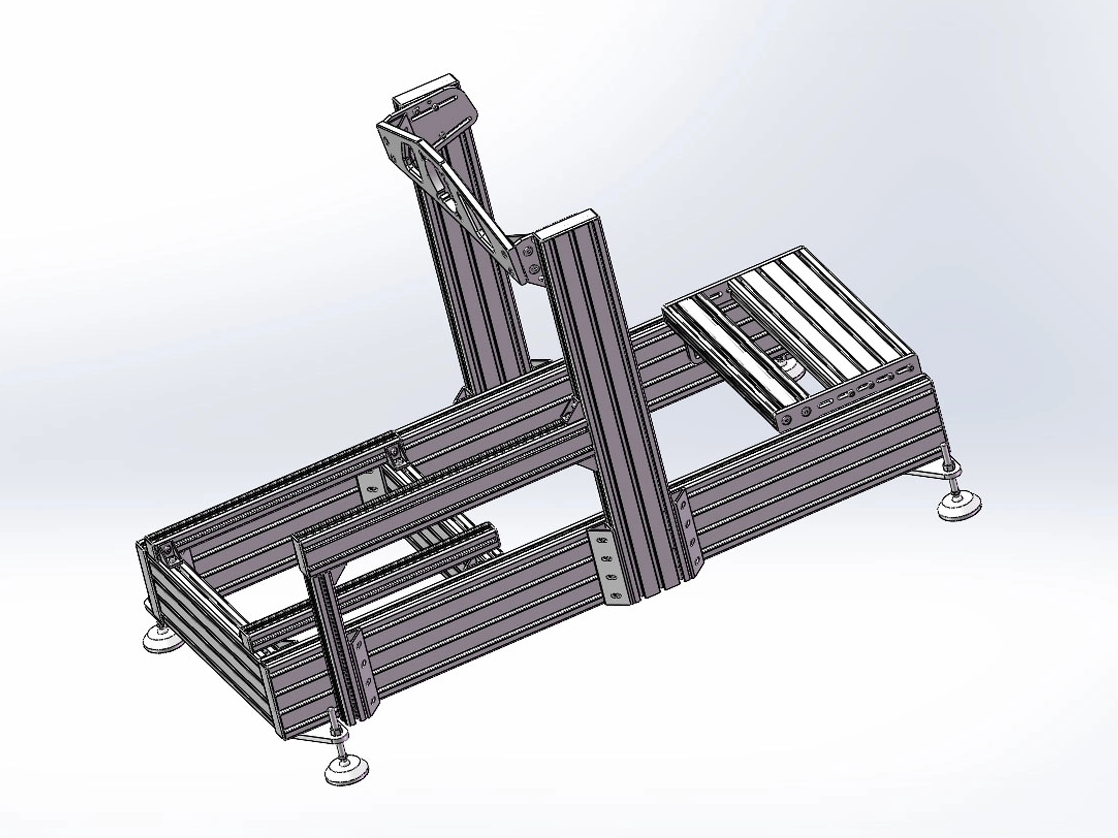

Key CNC Machines and Their Functions in Manufacturing

CNC machines come in various types, each designed for specific manufacturing tasks. Let's explore the most common CNC machines and their roles in creating precise parts across different industries.

CNC Milling Machines

CNC milling machines use rotating cutting tools to remove material from a workpiece. This process is ideal for creating complex shapes and intricate details. Milling machines can work with a variety of materials, including metals, plastics, and composites.

Examples of parts made using CNC milling machines:

Engine blocks

Turbine blades

Gearboxes

Custom brackets

CNC Turning Machines

CNC turning machines rotate the workpiece against a cutting tool to shape cylindrical parts. The material is held securely as the tool moves along different axes, making it perfect for creating precise cylindrical and conical shapes.

Key applications in manufacturing:

Automotive components like shafts and axles

Aerospace parts such as bushings and pistons

Medical devices like bone screws

CNC Routers and Plasma Cutters

CNC routers are primarily used for cutting softer materials like wood, plastic, and foam. These machines can create detailed patterns and complex shapes, commonly used in industries like furniture making and signage.

CNC plasma cutters use a high-temperature plasma torch to cut through metals. These machines are effective for sheet metal fabrication, where speed and precision are key.

Applications:

CNC routers: Furniture parts, signage, and interior panels.

CNC plasma cutters: Metal frames, industrial parts, and sheet metal designs.

CNC EDM (Electrical Discharge Machines)

CNC EDM machines use electrical sparks to remove material from a workpiece, providing high precision. This method is ideal for shaping hard metals, including alloys that are difficult to machine with conventional methods.

Applications in industries requiring fine detail work:

Aerospace: Turbine blades and other intricate parts.

Tool and die making: Molds and cavities.

Medical devices: Precision implants and surgical tools.

Is CNC Machining a Part of Subtractive Manufacturing?

CNC machining is a key method in subtractive manufacturing, where material is removed to create a part. Let’s compare subtractive manufacturing with its counterpart, additive manufacturing, and explore how CNC machining fits into this process.

Subtractive Manufacturing vs. Additive Manufacturing

Subtractive Manufacturing: In subtractive manufacturing, material is gradually removed from a solid block to create the desired shape. CNC machining is a prime example of this, where tools like mills and lathes cut away material to form intricate parts.

Additive Manufacturing: This process builds parts layer by layer, often using 3D printing technology. Material is added, rather than removed, making it suitable for creating complex geometries but often at a slower pace than subtractive methods.

How CNC Machining Fits into Subtractive Manufacturing

CNC machining plays a central role in subtractive manufacturing due to its precision and ability to create complex parts efficiently. It uses digital instructions to guide cutting tools in removing material from a workpiece.

Advantages of CNC machining in subtractive manufacturing:

High Precision: CNC machines can achieve tight tolerances, often within thousandths of an inch.

Efficiency: CNC machines can work continuously, reducing production time compared to manual methods.

Versatility: CNC machining can handle a wide range of materials, including metals, plastics, and composites, making it highly adaptable to various industries.

What Industries Rely on CNC Machining?

CNC machining is used across various industries due to its precision and ability to create complex parts. Here are some key sectors that depend on CNC technology.

Aerospace

In the aerospace industry, CNC machining is essential for producing high-precision components that must meet strict performance standards. Some examples include:

Turbine blades: Precision cutting for optimal performance in high-pressure environments.

Engine components: Parts that must withstand extreme temperatures and stresses.

Housings: Complex enclosures for aerospace systems and electronics.

Automotive

CNC machining is critical in the automotive sector, where accuracy is needed for safety and performance. Examples include:

Engine blocks: Precision milling for engine components.

Brackets: Structural parts that support various automotive systems.

Gears and suspension parts: CNC machining creates durable and high-performance components.

Medical

CNC machining is crucial for manufacturing medical devices and instruments that require high precision. Examples include:

Surgical instruments: Tools designed for accuracy and safety in delicate procedures.

Implants: Parts like hip replacements and dental implants, requiring biocompatibility and precision.

Medical devices: Components for diagnostic and monitoring equipment.

Electronics

The electronics industry relies on CNC machining to produce tiny, intricate components. Examples include:

Precision components: Parts for electronics that need tight tolerances.

PCB enclosures: Custom-made cases that protect delicate circuit boards.

Other Industries

CNC machining also serves various other sectors, such as:

Defense: Manufacturing parts for military vehicles, weapons, and equipment.

Consumer goods: Producing precision components for everyday products, such as appliances and tools.

The Benefits of CNC Machining in Manufacturing

CNC machining offers several advantages, making it a preferred method in modern manufacturing. Here are some key benefits:

Precision and Accuracy

CNC machines can achieve incredibly tight tolerances, often as small as ±0.0001 inches. This level of precision is essential for industries like aerospace and medical devices, where accuracy is crucial.

Efficiency and Speed

CNC machining drastically reduces cycle times compared to manual machining. Once set up, CNC machines can run continuously, allowing for faster production, especially in mass production environments. This speed reduces overall manufacturing costs.

Customization and Flexibility

CNC machining is perfect for creating custom parts and prototypes. Designers can make changes to the design quickly, and CNC machines can produce these customized parts without needing retooling, offering flexibility in small-batch production and rapid prototyping.

Consistency and Repeatability

The automated nature of CNC machines ensures that parts are produced with consistent quality. Unlike manual methods, which are prone to human error, CNC machines can replicate the same part design repeatedly, maintaining uniform quality across all units.

Common CNC Machining Processes in Manufacturing

CNC machining includes several key processes that help create a wide range of parts. Let's explore some of the most common CNC machining methods.

Milling

Milling involves using rotating cutting tools to remove material from a workpiece. This process is highly versatile and can create complex geometries, including pockets, slots, and detailed features. CNC milling is often used for parts requiring intricate shapes and precise surface finishes.

Applications:

Turning

Turning is a process where the workpiece is rotated while a stationary cutting tool removes material. This method is ideal for producing cylindrical and rotationally symmetric parts, such as shafts, pins, and rings. CNC turning machines use multiple axes to cut, shape, and finish the material.

Applications:

Automotive components like axles and bushings

Aerospace parts like spindles

Medical components such as bone screws

Drilling and Grinding

CNC drilling is used to create precise holes in materials, while CNC grinding ensures a smooth, finished surface. Drilling is often used for making holes of various sizes, while grinding is used to improve surface quality or achieve tight tolerances.

Applications:

Drilling: Holes for fasteners, assembly parts, or fluid channels

Grinding: Achieving smooth finishes on parts like gears or shafts

What Materials Are Used in CNC Machining?

CNC machining can work with a wide variety of materials, allowing manufacturers to create parts for different industries. Let’s look at the types of materials used in CNC machining and the factors that influence material selection.

Types of Materials CNC Machining Works With

1. Metals

- Aluminum: Lightweight and easy to machine, commonly used in automotive and aerospace parts.

- Steel: Strong and durable, ideal for high-stress components.

- Titanium: Corrosion-resistant and strong, perfect for aerospace and medical parts.

2. Plastics

- Materials like acrylic, Delrin, and Nylon are used for parts that require lightweight properties and resistance to wear.

3. Ceramics

- Used in specialized applications requiring high heat resistance and electrical insulation.

4. Composites

- Materials like carbon fiber and fiberglass are often used in industries requiring high strength-to-weight ratios.

Material Selection

When choosing a material for CNC machining, manufacturers consider:

Part functionality: What properties the part needs (strength, flexibility, etc.).

Machinability: How easy the material is to machine.

Cost: Material cost impacts the overall production cost.

Special Considerations

Heat Treatment

Some materials may need heat treatment (e.g., hardening or annealing) to improve their strength or durability.

Material Wear

Harder materials, like titanium or steel, may cause more wear on CNC tools, which requires frequent tool maintenance.

Challenges of CNC Machining in Manufacturing

While CNC machining offers many advantages, it also comes with its own set of challenges. Let's explore some of the key difficulties manufacturers face when using CNC machines.

High Initial Costs

CNC machines are expensive to purchase and set up. The cost of the machines themselves, along with the required software and tooling, can be significant. For smaller companies or startups, the initial investment may be a barrier to entry.

Skilled Labor

CNC machining requires skilled operators and technicians to run the machines effectively. These professionals must be trained in both the technical aspects of the machinery and the software that controls it. Finding and retaining qualified workers can be a challenge, especially as the demand for precision machining increases.

Material Waste

Though CNC machining is more efficient than many traditional methods, material waste can still occur, especially with complex designs. High-precision parts may result in scrap material during the cutting or shaping process. Proper planning and optimization can help reduce this waste, but it remains an ongoing challenge for manufacturers.

The Future of CNC Machining in Manufacturing

CNC machining continues to evolve, driven by new technologies and shifting market demands. Let's explore what the future holds for this essential manufacturing process.

Emerging Technologies in CNC Machining

Advancements in CNC machining technology are transforming how parts are made. Some of the key innovations include:

Multi-axis CNC machines: These machines can move in more than three directions, allowing for the production of more complex and precise parts.

Automation: With automated systems, CNC machines can operate more efficiently, reducing the need for human intervention and improving production speed.

AI integration: Artificial intelligence is enhancing CNC machines' ability to learn from data, making adjustments in real-time for better precision and efficiency.

Adapting to Growing Demand for Custom and High-Precision Parts

As industries demand more customized and intricate parts, CNC machining is adapting. Modern CNC machines are becoming more flexible, capable of handling small batch productions and prototypes without compromising on precision. This ability to produce both custom and high-precision parts makes CNC machining indispensable for sectors like aerospace, automotive, and medical devices.

CNC Machining in the Industry 4.0 Movement

CNC machining is a key player in the Industry 4.0 revolution. This movement emphasizes smart manufacturing, where machines are interconnected, and data is shared in real-time for better decision-making. CNC machines are now equipped with sensors and IoT capabilities, allowing for predictive maintenance, improved efficiency, and greater integration into digital production networks.

Conclusion

CNC machining is a vital part of modern manufacturing, offering precision and efficiency. As industries demand more custom and high-precision parts, CNC technology continues to evolve. The future looks bright, with emerging technologies like AI and multi-axis machines driving innovation. Explore CNC machining solutions to meet your specific manufacturing needs.

FAQ

Q: What is the difference between CNC machining and traditional machining?

A: CNC machining is computer-controlled, offering higher precision and repeatability, while traditional machining relies on manual operation, which can lead to inconsistencies.

Q: Can CNC machining be used for custom parts?

A: Yes, CNC machining is ideal for producing custom parts and prototypes, offering flexibility in design and quick modifications.

Q: How precise is CNC machining?

A: CNC machining can achieve tolerances as tight as ±0.0001 inches, making it highly precise for various industries.

Q: What industries benefit most from CNC machining?

A: Industries like aerospace, automotive, medical, and electronics benefit greatly from CNC machining due to its precision and ability to handle complex parts.

Q: How long does it take to machine a part using CNC?

A: CNC machining time varies depending on part complexity, material, and size, but it is generally faster than traditional methods, especially in high-volume production.