The industrial landscape has dramatically shifted with the rapid adoption of automation. Manufacturing sectors around the world are increasingly turning to automated production lines to meet rising demands for efficiency, precision, and cost savings. These lines are designed to operate without human intervention, relying on advanced robotics and sophisticated machinery to perform repetitive tasks with speed and accuracy.

The shift to automation is not just about replacing human labor; it’s about transforming the entire manufacturing process to enhance productivity, flexibility, and scalability. However, one of the key challenges that manufacturers face is ensuring that all components of the production line—whether it be machinery, conveyors, or assembly fixtures—work seamlessly together.

Enhancing Automation Efficiency: Precision and Flexibility

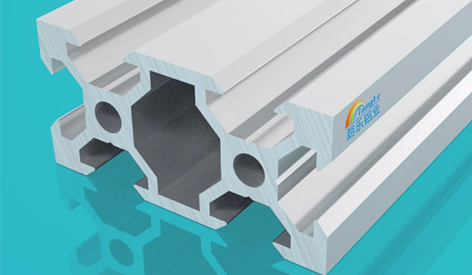

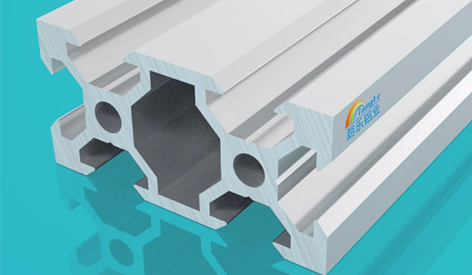

At the core of any automated assembly line is the need for high precision. Every piece of machinery must work in perfect coordination, ensuring that tasks are carried out without error or delay. In this environment, even the slightest misalignment can result in costly inefficiencies, defects, or system failures. V Slot Aluminium Profiles provide a robust solution to this problem by ensuring accurate positioning and easy alignment of machines, tools, and other components on the production line.

Precision Alignment and Positioning

V Slot Aluminium Profiles feature slots and grooves that allow for precise alignment of machinery and components. This level of precision is critical in automated settings, where even minor misalignments can disrupt the entire workflow. The ability to securely position machines and components using these profiles ensures that the assembly line operates smoothly, minimizing downtime and increasing throughput.

Modularity for Quick Adjustments

Automation requires flexibility, and production lines often need to be reconfigured to accommodate new products or processes. V Slot Aluminium Profiles excel in this area due to their modular design. These profiles can be easily assembled, disassembled, and adjusted without the need for specialized tools or complex procedures. Manufacturers can quickly modify the layout of their production lines, adding or removing components as needed to suit new requirements. This flexibility reduces downtime during transitions and allows businesses to adapt quickly to changing market demands.

Ease of Integration

Automated systems often include a variety of machinery, from robotic arms to conveyors and quality control equipment. V Slot Aluminium Profiles facilitate easy integration between these systems. Their standardized design allows them to be used in conjunction with a wide range of components, reducing the complexity of system integration and ensuring that all parts of the production line work in tandem.

Cost and Resource Efficiency: Long-Term Benefits for Businesses

In the fast-paced world of manufacturing, businesses are always looking for ways to reduce costs while maintaining or improving the quality of their products. The integration of V Slot Aluminium Profiles into automated assembly lines offers several long-term benefits that contribute to cost savings and resource efficiency.

Reduced Maintenance Costs

V Slot Aluminium Profiles are made from durable materials that are built to withstand the demands of high-speed, high-volume production environments. Their robustness means that they require less frequent maintenance, reducing downtime and preventing costly disruptions to the production process. In industries where uptime is crucial, the reliability of these profiles can have a significant impact on overall operational costs.

Minimized Need for New Equipment

One of the greatest advantages of V Slot Aluminium Profiles is their modularity. As production needs evolve, manufacturers often find themselves in need of new equipment or modifications to existing infrastructure. With traditional systems, this can involve significant costs for new machinery, installation, and downtime. However, V Slot Aluminium Profiles allow for easy modification of existing equipment, enabling manufacturers to repurpose and reconfigure their production lines with minimal expense. This can result in substantial savings, particularly for companies that need to adjust their operations frequently to meet changing market conditions.

Faster Setup and Downtime Reduction

Speed is of the essence in manufacturing, especially in industries where time-sensitive production is critical. The modular nature of V Slot Aluminium Profiles enables faster setup times and quicker adjustments between production cycles. By eliminating the need for complex tools or major infrastructure changes, businesses can significantly reduce downtime, allowing them to maximize the efficiency of their production lines.

Driving Sustainability: Reducing Waste and Optimizing Energy Use

Sustainability is a growing concern in the manufacturing world, and companies are increasingly seeking ways to reduce their environmental footprint. Automated production lines, powered by V Slot Aluminium Profiles, contribute to sustainability in a number of ways.

Waste Reduction

V Slot Aluminium Profiles are made from recyclable materials, making them an environmentally friendly choice for construction and manufacturing. Moreover, their modular design minimizes material waste. Rather than discarding entire systems or large components during modifications, businesses can simply adjust their existing setups, reducing the need for new materials. This results in lower consumption of raw materials and less waste sent to landfills.

Energy Efficiency

Automation is known for its ability to streamline production processes and optimize energy usage. Automated systems run more efficiently than traditional manual setups, using less power and requiring fewer resources to perform tasks. V Slot Aluminium Profiles help optimize the design of these systems by reducing friction, ensuring smoother movement of components and lowering energy consumption. The more efficient a production line is, the less energy it consumes, which not only saves costs but also reduces the company’s carbon footprint.

Support for Green Manufacturing Practices

Many companies are now focusing on “green manufacturing” practices, which aim to reduce environmental impact while maintaining product quality and profitability. By incorporating V Slot Aluminium Profiles into their automated systems, manufacturers can take advantage of the profiles' sustainable properties, reducing the need for environmentally damaging practices like excessive energy use or large-scale material waste. This is a step forward in aligning production processes with broader sustainability goals.

Increasing Production Line Versatility: Meeting Market Demands

Modern manufacturing is characterized by its need to quickly adapt to market trends and customer demands. Customization, quick turnarounds, and rapid innovation are all necessary to stay competitive. V Slot Aluminium Profiles allow businesses to respond to these demands by offering exceptional flexibility in production line design.

Rapid Adaptation to Market Changes

In today’s fast-moving markets, manufacturers often need to adjust their production lines to accommodate new products, designs, or batch sizes. V Slot Aluminium Profiles enable companies to quickly reconfigure their setups, reducing lead times and allowing them to respond faster to customer needs. Whether adjusting for seasonal trends or launching a new product, these profiles make it easier to make rapid adjustments to production lines.

Supporting Mass Customization

As customers increasingly demand personalized products, manufacturers must find ways to accommodate small-batch or highly customized orders. V Slot Aluminium Profiles support mass customization by making it easier to modify assembly lines on the fly. These profiles allow for quick changes in the production setup, ensuring that even highly customized orders can be produced efficiently without requiring extensive downtime or new equipment.

Scalability for Future Growth

V Slot Aluminium Profiles also future-proof production lines by providing a scalable solution for growing businesses. As a company expands, it can easily add or reconfigure its production lines to meet increasing demand without major capital investment. This scalability ensures that manufacturers can continue to grow without being limited by their infrastructure.

Conclusion

The integration of V Slot Aluminium Profiles into automated assembly lines is transforming modern manufacturing. These profiles not only offer precision, flexibility, and durability but also bring long-term cost savings, energy efficiency, and sustainability to the production process. As industries continue to embrace automation, the importance of adaptable, modular components like V Slot Aluminium Profiles will only increase.

To discover more about Hunan Langle Technology Co., Ltd. and explore their range of V Slot Aluminium Profile products, visit their official website at www.hnlangle.com. Known for high-quality and customizable aluminium profiles, Hunan Langle offers solutions ideal for building flexible, modular systems in various applications, from automation and construction to furniture and machinery design.