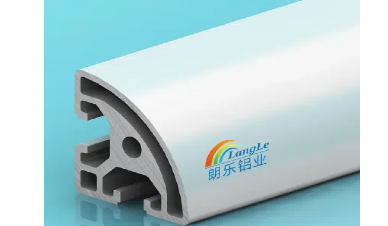

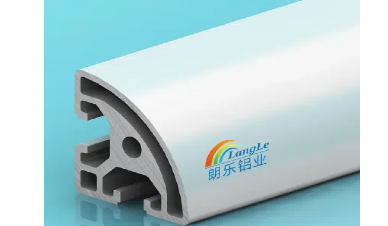

T-slot aluminium extrusions are versatile, high-strength profiles commonly used in industrial framing, automation systems, machinery guarding, workstations, and even DIY projects. Their modular design allows for quick assembly and reconfiguration, making them a staple in modern manufacturing and construction. Central to their functionality are the T slots—the channels along the extrusion that accommodate fasteners, connectors, and accessories. But not all T slots are the same. Understanding the different types of T slots is essential for selecting the right extrusion for your application.

Understanding T-Slot Aluminium Extrusions

Before diving into the types, it’s important to understand the basics. T-slot aluminium extrusions are made by pushing heated aluminium billets through a die to create a precise cross-sectional shape. The slots resemble the letter "T," providing a track for nuts, bolts, and specialized connectors. This design allows for adjustable and robust connections without the need for welding or complex machining.

The advantages of T-slot aluminium extrusions include:

1. Modularity

One of the greatest strengths of T-slot systems is their inherent modularity. Components can be easily added, removed, or repositioned without requiring major disassembly.

2. Strength-to-Weight Ratio

Aluminium extrusions offer an impressive strength-to-weight ratio. They provide robust structural support comparable to steel but at a fraction of the weight.

3. Corrosion Resistance

Many T-slot aluminium profiles are anodized or coated to resist oxidation, making them durable in indoor and outdoor environments.conditions, making them a reliable choice for both industrial and architectural projects.

4. Customization

T-slot extrusions can be easily cut, drilled, or machined to suit specific design requirements. They can also be fitted with a wide range of accessories, including brackets, panels, hinges, and fasteners, allowing for highly customized solutions.

Common T-Slot Configurations

T-slot aluminium extrusions come in a wide variety of sizes, shapes, and slot widths, each designed to meet specific structural and functional requirements. The type of T slot directly influences which fasteners, connectors, and accessories can be used, as well as the maximum load-bearing capacity of the assembly. Selecting the right T-slot profile ensures stability, versatility, and long-term durability for your project. Below are the most common configurations and their typical applications:

1. Standard T Slot

The standard T slot is the most widely used profile in industrial and commercial applications. It features a uniform width and depth designed to accommodate standard T-slot nuts and bolts. This makes it ideal for general-purpose framing and a wide range of modular construction needs.

Applications: Machine enclosures, light-duty workstations, shelving frames, and general-purpose structural assemblies.

Advantages:

Widely available and compatible with a broad selection of accessories.

Cost-effective for most industrial and commercial projects.

Simple to work with for both professionals and DIY users.

Considerations:

2. Mini T Slot

Mini T slots are smaller versions of the standard profile, designed for applications where space is limited or the loads are lighter. Their compact design allows for delicate assemblies without compromising stability in smaller-scale projects.

Applications: Laboratory equipment frames, small automation devices, light shelving, and DIY projects that require precision and compactness.

Advantages:

Lightweight and easy to handle.

Provides flexibility in compact or constrained spaces.

Suitable for delicate assemblies that don’t require heavy-duty support.

Considerations:

3. Wide T Slot

Wide T slots are designed to accept larger fasteners, nuts, and bolts, providing a stronger, more secure connection. This makes them ideal for heavy-duty or high-stress applications where stability and strength are paramount.

Applications: Conveyor systems, industrial machinery frames, automated assembly lines, and other high-load installations.

Advantages:

Enhanced stability and structural strength.

Supports larger accessories, panels, and attachments.

Reduces the risk of slippage or loosening under heavy loads.

Considerations:

Requires more material, making the extrusion slightly heavier and more expensive.

Assembly may be less compact compared to standard or mini T slots.

4. Slotless or Blind Slot

Some extrusions feature slotless or blind T slots, where the channel is partially closed. This design is ideal when a clean aesthetic is required or when additional rigidity is needed without visible fasteners.

Applications: Display frames, architectural panels, protective covers, and premium or aesthetic-focused assemblies.

Advantages:

Smooth, sleek appearance without exposed hardware.

Adds extra rigidity due to the closed profile.

Reduces the risk of dust or debris entering the slot.

Considerations:

5. Multi-T Slot Profiles

Multi-T slot extrusions feature multiple slots on each side or around the profile, offering extensive connection points and greater assembly versatility. This type is particularly useful for complex or modular systems requiring frequent adjustments.

Applications: Robotic frames, modular workstations, industrial machinery, and projects requiring high adaptability.

Advantages:

Multiple mounting points allow for highly customizable assemblies.

Accommodates heavy or complex structures with numerous attachments.

Ideal for scalable and reconfigurable setups.

Considerations:

Choosing the Right T Slot

Selecting the correct T-slot type depends on several factors:

Load Requirements: Determine the weight and stress the extrusion will bear. Wide or multi-slot profiles are ideal for heavier loads.

Assembly Flexibility: If frequent adjustments are needed, standard or mini T slots are easier to work with.

Space Constraints: Smaller slots suit compact designs, while wider slots may be bulky in tight spaces.

Aesthetic Considerations: Slotless or blind slots are preferable where visual appearance is important.

Accessory Compatibility: Ensure the T slot matches the fasteners, connectors, and panels you plan to use.

Accessories for T-Slot Aluminium Extrusions

T slots are only as versatile as the accessories they support. Some common components include:

T-Nuts and Bolts: Slide into the slot to fasten panels and brackets.

Corner Brackets: Strengthen joints at 90-degree angles.

End Caps: Protect slot edges and provide a finished appearance.

Linear Motion Components: Bearings, rails, and slides can be integrated for automation.

Panels and Covers: Attach protective sheets or decorative panels securely.

Using the correct combination of T slot type and accessories ensures maximum structural integrity, flexibility, and longevity.

Advantages of Understanding T-Slot Types

Choosing the right T-slot profile has tangible benefits:

Cost Efficiency: Avoid over-engineering with unnecessarily large or heavy profiles.

Simplified Assembly: Proper slot selection reduces assembly time and errors.

Long-Term Flexibility: Allows for future modifications without replacing the entire structure.

Optimized Load Distribution: Correctly matched slots prevent stress concentration and material fatigue.

Conclusion

T-slot aluminium extrusions are a cornerstone of modern modular construction and industrial framing. Understanding the different types of T slots—from standard and mini to wide, blind, and multi-slot profiles—ensures that you select the right solution for your specific project requirements.

Whether building machinery frames, workstations, protective enclosures, or DIY automation setups, choosing the correct T-slot type maximizes structural strength, assembly efficiency, and adaptability.

For businesses and individuals seeking high-quality T-slot aluminium extrusions, Hunan Langle Technology Co. offers a wide range of profiles and accessories to suit diverse industrial and commercial applications. Contacting them can help you find the best T-slot solutions tailored to your needs, ensuring your projects are both durable and versatile.