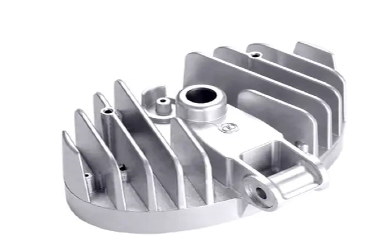

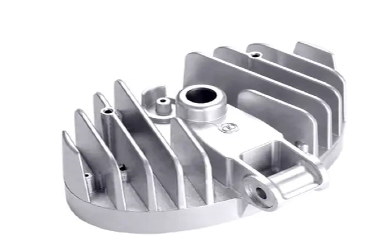

CNC milling is a precise manufacturing process that uses computer-controlled machines to shape aluminum parts with high accuracy. It is widely used across industries such as aerospace, automotive, electronics, and medical devices to produce complex and detailed components. While CNC milling ensures dimensional accuracy and precision, the surface finish of aluminum parts plays an equally important role in their performance and appearance. The right surface finish can improve the part's resistance to corrosion, wear, and environmental factors, while also enhancing its aesthetic appeal. Whether for functional purposes, like adding durability, or for cosmetic reasons, like achieving a smooth, shiny look, selecting the correct finish is essential to meet the specific requirements of each application.

Common Aluminum CNC Milling Finishes

1.Anodizing:

Anodizing is an electrochemical process that forms a thick, durable oxide layer on the surface of aluminum parts, significantly improving their resistance to corrosion and wear. It also enhances the appearance, offering a range of colors that can be achieved through dyeing. Anodized finishes are ideal for outdoor and industrial applications where durability and corrosion resistance are crucial, such as in automotive, aerospace, and architectural components. This finish increases the lifespan of aluminum parts, making it one of the most popular choices for high-performance applications.

2. Powder Coating:

Powder coating provides a thicker, more protective layer than traditional wet painting. It involves applying a dry powder, which is then cured under heat to form a hard, durable finish. This coating enhances both the appearance and resistance of aluminum parts to corrosion, UV damage, and physical wear. Additionally, powder coating offers a broad range of colors and textures, making it a versatile option for both functional and aesthetic purposes. It's commonly used for consumer goods, outdoor furniture, and automotive parts.

3. Brushing:

Brushing is a mechanical process that involves using abrasive tools to create a matte or satin finish on the surface of aluminum. This technique is often used for aesthetic purposes, providing a sleek, textured look while maintaining the aluminum's natural metal appearance. Brushed aluminum is frequently used in applications where a contemporary or industrial design is desired, such as in consumer electronics, kitchen appliances, or architectural fixtures.

4. Polishing:

Polishing aluminum parts results in a shiny, reflective surface that is highly valued for decorative and high-end applications. This finish is achieved through a multi-step process involving abrasives and buffing to create a mirror-like shine. Polished aluminum is often used in the automotive, consumer electronics, and luxury goods industries, where appearance and presentation are paramount. It not only enhances the aesthetic but also reduces the likelihood of corrosion by smoothing out the surface.

5.Chromate Conversion Coating:

Chromate conversion coating, often referred to as chromating, is a chemical process that applies a thin, protective layer to the surface of aluminum. This finish is primarily used in aerospace, military, and defense applications due to its excellent corrosion resistance and the ability to withstand harsh environmental conditions. Chromate conversion coatings provide a slightly yellowish tint and act as a corrosion inhibitor, making it suitable for parts exposed to high-stress environments like aircraft components and military equipment.

6.Painting:

Painting aluminum parts is a common method to enhance their appearance and protect them from corrosion, UV radiation, and other environmental factors. A wide range of colors and finishes (e.g., matte, glossy, or textured) can be achieved through various painting techniques, including spray painting or electrostatic coating. Painting is often used in both functional and decorative applications, such as automotive bodies, architectural elements, and consumer products, offering flexibility in design and added protection.

Functional vs Aesthetic Finishes

1.Functional Finishes:

Functional finishes are primarily chosen for their performance attributes, enhancing the durability and functionality of aluminum parts. These finishes are applied to protect the part from environmental stress, wear, and corrosion. Key examples include:

Anodizing: This finish not only improves corrosion resistance but also increases wear resistance, making it ideal for outdoor and high-performance applications where parts are exposed to harsh conditions.

Powder Coating: Offering a thicker, more protective layer, powder coating is often used in environments where parts face heavy abrasion or UV exposure, providing both durability and weather resistance.

Chromate Conversion Coating: A vital finish in aerospace and military industries, chromating offers superior protection against corrosion and is essential for parts exposed to extreme conditions, such as aircraft components.

Functional finishes play a crucial role in extending the lifespan of aluminum parts, reducing maintenance, and ensuring optimal performance throughout the part's lifecycle. These finishes are typically chosen with a focus on preserving the part’s structural integrity and resistance to damage.

2.Aesthetic Finishes:

Aesthetic finishes are applied to aluminum parts to enhance their visual appeal. While they may also provide some protection, their primary purpose is to improve the appearance of the part. Common aesthetic finishes include:

Polishing: This produces a shiny, reflective surface that enhances the appearance of aluminum parts, often used for decorative or luxury applications.

Brushing: This technique creates a matte or satin finish, commonly used in consumer electronics, appliances, or architectural fixtures to provide a modern or industrial look.

Painting: A popular option for adding vibrant color or achieving a specific texture, painting is often used in consumer products, signage, and decorative components.

While aesthetic finishes enhance the visual appeal, they may not always offer the same level of durability or protection as functional finishes. However, certain aesthetic finishes like powder coating or anodizing can provide both a beautiful appearance and increased durability.

3.Impact on Durability and Maintenance:

Finishes chosen for functionality often have a significant impact on the long-term durability of aluminum parts. For example, anodizing or chromate conversion coatings can prevent corrosion and wear, extending the life of parts in demanding environments. On the other hand, aesthetic finishes may need more frequent maintenance or reapplication depending on the exposure to wear or environmental elements. For instance, polished surfaces may require regular cleaning and care to maintain their shine, while painted surfaces might need touch-ups if they chip or fade.

How to Choose the Right Finish

1.Factors to Consider When Selecting a Finish:

Choosing the right finish for aluminum CNC milling parts depends on several factors:

Part Application: Consider the function of the part. If the part is used in a high-wear environment, finishes like anodizing or powder coating provide enhanced durability. For decorative purposes, a polished or brushed finish might be ideal.

Environment: Think about where the part will be used. Outdoor parts require finishes that offer resistance to weather, moisture, and UV rays, such as anodizing or powder coating. For indoor applications, aesthetic finishes like painting or polishing may be sufficient.

Desired Aesthetics: Determine the visual appeal you want for the part. A polished finish offers a shiny, high-end look, while brushed aluminum gives a sleek, matte appearance. Color options can also influence your choice, with powder coating and painting offering a wide range of colors.

2.Consulting with CNC Service Providers:

It's always a good idea to consult with CNC machining service providers when selecting the right finish. They can recommend the best option based on your part’s requirements, ensuring both functionality and aesthetics are met. CNC providers can also help you balance cost and performance, offering guidance on which finishes will provide the best protection and appearance for your specific application.

FAQ

1.What is anodizing, and why is it used for aluminum CNC milling parts?

Anodizing is an electrochemical process that creates a thick, durable oxide layer on the surface of aluminum. This finish enhances corrosion resistance, wear resistance, and durability, making it ideal for outdoor or high-performance parts. Anodizing also allows for coloring the aluminum, providing both functional and aesthetic benefits.

2.Can I choose custom colors for my aluminum CNC milling parts?

Yes, custom colors can be achieved with anodizing and powder coating. Anodizing offers a range of colors through dyeing the oxide layer, while powder coating provides a more diverse color palette and finish options. Both finishes allow for tailored aesthetics to suit your design needs.

3.How does polishing affect the durability of aluminum parts?

Polishing aluminum creates a shiny, reflective surface that is visually appealing but may offer limited protection. While it can reduce the likelihood of corrosion by smoothing the surface, polished parts are more prone to scratching and require regular maintenance to retain their appearance. For better durability, polishing is often combined with other protective finishes like anodizing.

4.Is powder coating a better option than painting for aluminum CNC milling?

Powder coating generally provides a more durable finish than traditional painting. It creates a thicker, more protective layer that is resistant to chipping, fading, and corrosion. While painting offers more color variety, powder coating is often preferred for its superior protection and longer-lasting finish, especially in outdoor or high-abrasion environments.

Conclusion

In conclusion, the finish applied to aluminum CNC milling parts plays a crucial role in both their performance and appearance. Whether it’s anodizing for enhanced durability, powder coating for superior protection and color options, or polishing for a high-end aesthetic, each finish offers distinct advantages depending on the part’s intended use. Functional finishes like anodizing and chromate conversion coatings are essential for parts exposed to harsh environments, while aesthetic finishes like brushing and painting are perfect for products where appearance is key. When selecting a finish, consider the part’s application, the environment it will be used in, and the desired look. Consulting with your CNC service provider can help you choose the best finish that balances durability, functionality, and aesthetics, ensuring your aluminum parts perform optimally while maintaining their visual appeal.