Introduction

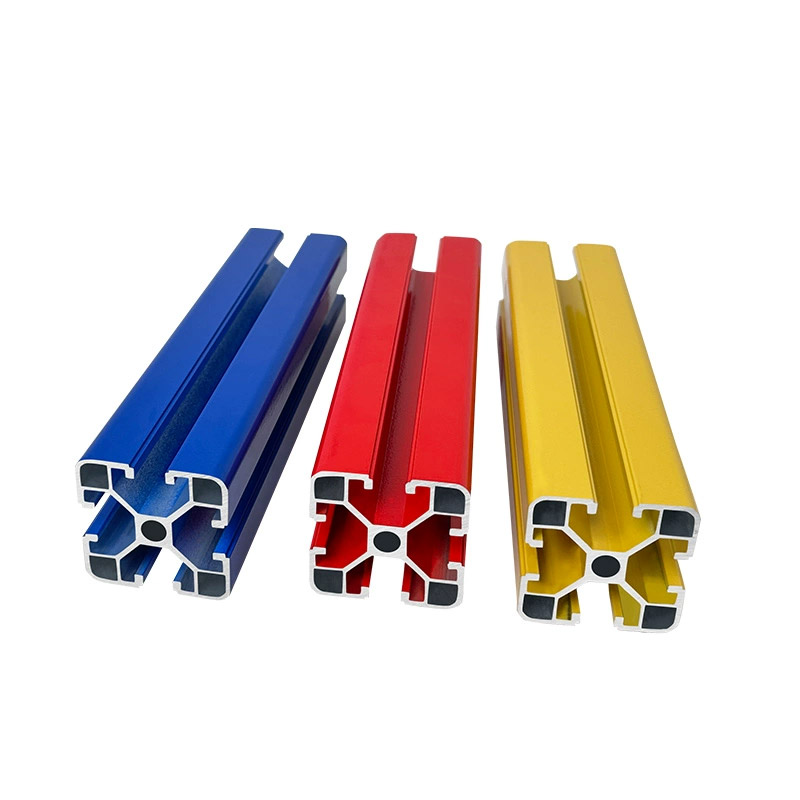

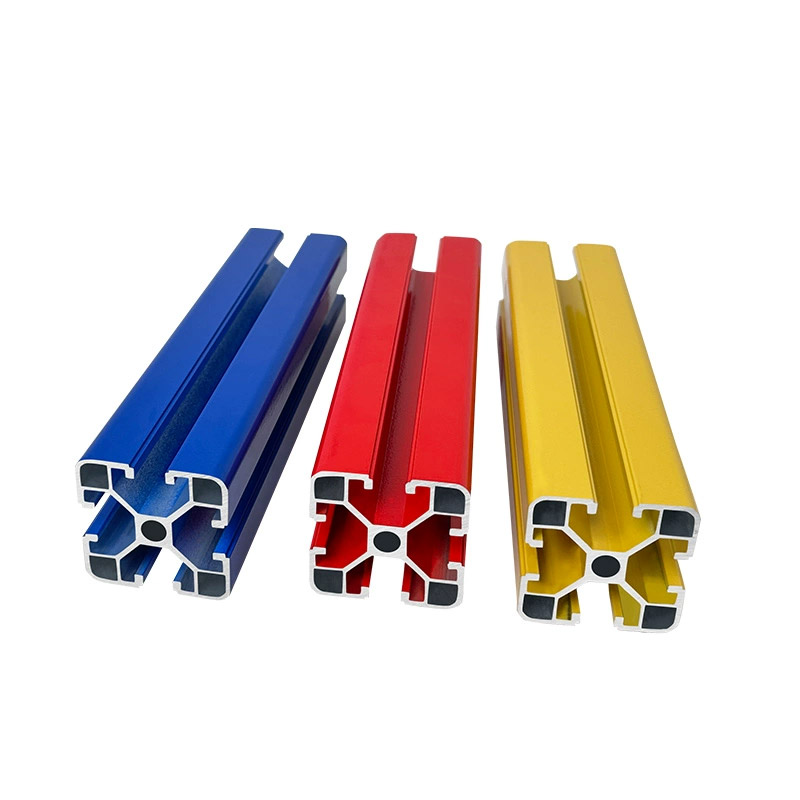

Aluminum extrusion scrap is an integral aspect of the aluminum industry, playing a crucial role in sustainability and cost-efficiency. Understanding what constitutes aluminum extrusion scrap and how it is managed is vital for professionals in the manufacturing and recycling sectors. This article delves into the intricacies of aluminum extrusion scrap, its sources, processing methods, and its significance in the circular economy. By exploring these facets, we aim to provide a comprehensive overview that underscores the importance of recycling practices in the aluminum extrusion industry. The concept of Aluminum Extrusion is central to this discussion, as it not only defines the process but also the by-products that become scrap.

Understanding Aluminum Extrusion Scrap

Aluminum extrusion scrap refers to the excess material generated during the aluminum extrusion process. This scrap can originate from various stages, including the initial billet preparation, the extrusion process itself, or from post-production trimming and machining. The scrap consists of aluminum alloy remnants that are not part of the final extruded product. Knowing the composition and characteristics of this scrap is essential for efficient recycling and reintroduction into the production cycle.

Sources of Aluminum Extrusion Scrap

The primary sources of aluminum extrusion scrap include:

Trimmings from the ends of extruded profiles.

Off-spec or rejected extruded parts due to quality control failures.

Machining chips resulting from the processing of extruded components.

These sources contribute to a substantial amount of scrap, which, if managed properly, can be recycled efficiently. The recycling of this scrap not only conserves resources but also reduces the environmental impact of aluminum production.

Composition and Characteristics

Aluminum extrusion scrap predominantly comprises aluminum alloys, primarily from the 6000 series, which are commonly used in extrusion due to their excellent mechanical properties and extrudability. The purity and alloy composition of the scrap are critical factors that determine its recyclability. Contamination with other metals or materials can complicate the recycling process, necessitating thorough sorting and cleaning procedures.

Processing of Aluminum Extrusion Scrap

The processing of aluminum extrusion scrap involves several stages designed to prepare the material for re-melting and reuse. The key steps include collection, sorting, cleaning, and melting. Each of these steps is crucial in ensuring that the recycled aluminum meets the required quality standards for subsequent applications.

Collection and Segregation

Efficient collection systems within manufacturing facilities are essential for maximizing scrap recovery. Segregation at the source involves separating aluminum scrap from other materials to prevent contamination. This practice enhances the quality of the scrap and reduces processing costs. Dedicated collection bins and employee training programs can improve segregation efficiency.

Cleaning and Preparation

Before recycling, the scrap must be cleaned to remove any contaminants such as lubricants, coatings, or other non-metallic materials. Cleaning processes may include mechanical abrasion, chemical treatments, or thermal processes. Proper cleaning ensures that the recycled aluminum maintains its material properties and is free from impurities that could affect the quality of new extrusions.

Melting and Refining

The cleaned scrap is then melted in a furnace. During melting, alloying elements may be added to adjust the composition to the desired specifications. Refining processes remove remaining impurities, resulting in high-quality aluminum ready for extrusion. The efficiency of the melting process is critical for energy conservation and minimizing emissions.

Environmental and Economic Impacts

Recycling aluminum extrusion scrap has significant environmental benefits. Recycling aluminum requires only about 5% of the energy needed to produce primary aluminum from bauxite ore. This substantial energy saving leads to a reduction in greenhouse gas emissions and conserves natural resources. Economically, recycling scrap reduces material costs for manufacturers and can enhance profitability.

Contribution to the Circular Economy

The circular economy model emphasizes the importance of keeping materials in use for as long as possible. Aluminum's recyclability without loss of properties makes it ideal for this model. By effectively recycling extrusion scrap, manufacturers contribute to a more sustainable economy and reduce the environmental footprint of their products.

Quality Control in Recycling

Maintaining quality throughout the recycling process is essential. This involves:

Regularly analyzing the chemical composition of the recycled aluminum.

Implementing stringent sorting protocols to prevent contamination.

Using state-of-the-art melting and casting technologies.

High-quality recycled aluminum can perform on par with primary aluminum, ensuring that products meet industry standards and customer expectations.

Technological Advances in Scrap Processing

Advancements in technology have significantly improved the efficiency of aluminum scrap processing. Innovations include:

Automated sorting systems utilizing sensors and AI for better separation.

Improved furnace designs that enhance energy efficiency.

Advanced filtration systems that reduce emissions during melting.

These technologies contribute to more sustainable practices and help manufacturers meet environmental regulations.

Regulatory Considerations

Compliance with environmental regulations is a critical aspect of scrap management. Regulations may pertain to:

Emission standards during melting and processing.

Waste disposal practices for non-recyclable materials.

Documentation and reporting of recycling activities.

Adhering to these regulations not only avoids legal penalties but also enhances a company's reputation for environmental responsibility.

Case Studies in Aluminum Extrusion Scrap Recycling

Examining real-world examples provides insights into best practices. Companies that have successfully integrated scrap recycling into their operations often report:

Reduced raw material costs by up to 30%.

Lowered energy consumption and operating expenses.

Enhanced corporate image and customer satisfaction.

These case studies demonstrate the tangible benefits of effective scrap management and recycling.

Challenges in Scrap Recycling

Despite the benefits, several challenges exist:

Contamination with other metals can reduce recyclability.

Fluctuating market prices for recycled aluminum affect profitability.

Initial investment costs for advanced recycling technology can be high.

Addressing these challenges requires strategic planning and investment in technology and training.

Future Outlook of Aluminum Extrusion Scrap

The future of aluminum extrusion scrap recycling is promising, with trends indicating increased emphasis on sustainability. The industry is likely to see:

Greater adoption of circular economy principles.

Continued technological advancements improving efficiency.

Stronger regulations driving better environmental practices.

Companies that proactively invest in recycling infrastructure will be better positioned to meet future demands and regulations.

Role of Industry Collaboration

Collaboration among industry stakeholders can enhance recycling efforts. Sharing best practices and developing industry standards can lead to more uniform and efficient recycling processes. Organizations may also collaborate with government agencies to shape favorable policies and incentives.

Innovations in Recycling Technologies

Emerging technologies such as laser-induced breakdown spectroscopy (LIBS) and X-ray fluorescence (XRF) are improving scrap sorting accuracy. These technologies enable rapid identification of alloy compositions, facilitating better segregation and higher-quality recycled aluminum.

Economic Impact on the Aluminum Market

The recycling of aluminum extrusion scrap significantly influences the aluminum market. By providing a steady supply of secondary aluminum, scrap recycling can:

Stabilize aluminum prices by balancing supply and demand.

Reduce dependence on imported raw materials.

Encourage domestic industry growth and job creation.

Understanding these market dynamics helps businesses make informed decisions regarding production and investment strategies.

Sustainability and Corporate Responsibility

Incorporating aluminum extrusion scrap recycling into corporate sustainability strategies demonstrates a company's commitment to environmental stewardship. This can enhance brand image, meet consumer expectations for eco-friendly practices, and potentially open up new market opportunities.

Practical Guidelines for Scrap Management

To optimize scrap recycling, companies should consider the following guidelines:

Conduct regular audits of scrap generation and recycling processes.

Invest in employee training on waste reduction and segregation practices.

Establish partnerships with specialized recycling firms.

Implement continuous improvement programs focused on sustainability.

These practices can lead to significant improvements in recycling efficiency and cost savings.

Conclusion

Aluminum extrusion scrap represents both a challenge and an opportunity for the aluminum industry. Effective management and recycling of this scrap are essential for environmental sustainability, economic efficiency, and compliance with regulatory standards. By understanding the nature of aluminum extrusion scrap and implementing best practices in recycling, companies can significantly reduce waste, conserve resources, and contribute positively to the circular economy. The role of Aluminum Extrusion in this context is pivotal, as it not only defines the processes that generate scrap but also offers pathways for recycling and reuse. Embracing these strategies ensures that the aluminum industry remains sustainable and resilient in the face of growing environmental and economic challenges.

"}