Introduction

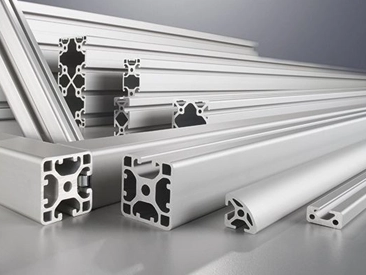

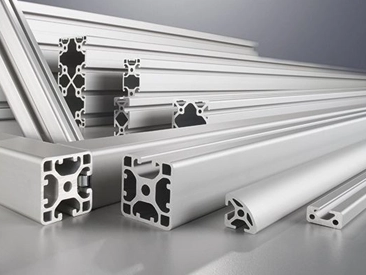

Extrusion is a fundamental process in material manufacturing, playing a pivotal role in shaping metals and polymers into desired cross-sectional profiles. Despite its widespread application, extrusion faces significant challenges that can affect the quality and efficiency of the end products. Understanding these challenges is crucial for improving production processes and achieving optimal results. One of the most pressing issues in extrusion is the occurrence of defects that compromise the integrity of materials, particularly in Aluminum Extrusion. This article delves into the major problems encountered in extrusion processes, with a focus on identifying causes and proposing solutions to mitigate these issues.

Understanding Extrusion Defects

Extrusion defects are imperfections that occur during the extrusion process, leading to suboptimal product quality. These defects can manifest as surface cracks, internal voids, dimensional inaccuracies, and texture inconsistencies. The primary causes of extrusion defects include improper temperature control, die design flaws, material impurities, and inadequate process parameters.

Surface Cracks and Fissures

Surface cracks are one of the most common issues in extrusion, particularly when processing high-strength alloys. These cracks occur due to tensile stresses exceeding the material's capacity during extrusion. Factors contributing to surface cracks include excessive extrusion speed, low billet temperature, and high friction between the material and the die. For instance, in Aluminum Extrusion, maintaining an optimal temperature and lubrication can significantly reduce the occurrence of surface defects.

Internal Void Formation

Internal voids or cavities compromise the structural integrity of extruded products. These voids typically result from improper billet preparation, such as inadequate degassing or contamination. In addition, rapid cooling rates can trap gases within the material matrix. Advanced techniques like vacuum extrusion and controlled cooling can help minimize internal voids.

Die Design and Its Impact

The die is a critical component in the extrusion process, dictating the shape and quality of the extruded product. Flaws in die design can lead to uneven material flow, causing defects such as warping or dimensional inaccuracies.

Flow Imbalance and Dead Zones

An imbalanced flow through the die can create regions where the material stagnates, known as dead zones. These areas can lead to material degradation and inclusion of impurities. Computational Fluid Dynamics (CFD) simulations are increasingly used to optimize die design, ensuring uniform flow and reducing the risk of defects.

Die Wear and Maintenance

Over time, dies can wear down due to high-pressure and high-temperature conditions, affecting product quality. Routine maintenance and the use of wear-resistant materials, such as tool steels with appropriate coatings, enhance die longevity and performance.

Material Considerations

The choice of material significantly influences the extrusion process and potential problems. Material purity, grain structure, and mechanical properties must be carefully considered.

Material Impurities and Contamination

Impurities in the raw material can lead to inclusions and weaknesses in the extruded product. Implementing strict quality control measures, such as spectrographic analysis and employing high-purity billets, can mitigate these issues.

Grain Structure and Anisotropy

During extrusion, materials can develop anisotropic grain structures, affecting mechanical properties. Proper control of processing parameters and post-extrusion treatments, like annealing, can promote a more uniform grain structure, enhancing product reliability.

Process Parameter Optimization

Optimizing extrusion parameters is essential for minimizing defects. Parameters such as extrusion speed, temperature, and lubrication directly impact the quality of the extruded product.

Extrusion Speed Control

High extrusion speeds can lead to increased friction and temperature, causing defects like surface cracking. Conversely, too slow speeds reduce productivity and may induce other defects. Achieving the optimal speed requires balancing these factors based on material properties and desired outcomes.

Temperature Management

Temperature plays a crucial role in material flow and microstructure development. Precise temperature control ensures consistent viscosity and prevents defects related to thermal gradients. Utilizing advanced heating and cooling systems can aid in maintaining optimal temperatures throughout the process.

Case Studies and Industry Examples

Several industries have implemented innovative solutions to address extrusion problems. For example, aerospace manufacturers require high-quality extrusions for structural components. By investing in state-of-the-art equipment and process monitoring, these companies have reduced defects significantly.

Advancements in Aluminum Extrusion

The aluminum extrusion industry has seen substantial improvements through the adoption of technology and process enhancements. Companies specializing in Aluminum Extrusion have developed proprietary alloys and heat treatments to enhance performance and reduce defects.

Implementation of Artificial Intelligence

Artificial Intelligence (AI) and machine learning algorithms are being utilized to predict and control extrusion parameters in real-time. This technology allows for immediate adjustments, minimizing the occurrence of defects and improving overall efficiency.

Conclusion

Extrusion remains a vital process in manufacturing, but it is not without its challenges. The major problems stem from defects caused by material issues, die design, and process parameters. Addressing these problems requires a multifaceted approach that includes material selection, die optimization, and precise control of extrusion conditions. As technology advances, the integration of AI and improved materials science will continue to enhance the quality and efficiency of extrusion processes. Stakeholders in industries reliant on extrusion must remain vigilant in adopting best practices and innovations to overcome these challenges and achieve superior products.

Recommendations for Future Research

Continued research into material science and process engineering is essential for further advancements in extrusion. Studying the effects of nano-materials and composite billets could lead to breakthroughs in reducing defects. Collaboration between academia and industry will play a crucial role in developing new methodologies and technologies to address the persistent challenges in extrusion.

Acknowledgments

We extend our gratitude to the organizations and professionals who have contributed to the advancement of extrusion technology. Their dedication to overcoming the major problems in extrusion has significantly impacted the efficiency and quality of manufacturing processes worldwide.

"}